Having been branded as a global leader in automatic bagging solutions for pre-made pouches, WeighPack Systems has made sure that their bag filling machines are capable of automatically opening, filling, and sealing a diverse range of pouches including doypack or stand-up (also referred as SUP or SURP), pillow, 4 sided seal, 3 side seal and quad pouches with zippers.

DOYPACK SYSTEM

Doypacks or most commonly known as stand up pouches and may sometimes be referred to as SUP or SURP are above any other conventional packaging bag styles because they offer both the manufacturer and the consumer advantages that the former certainly do not have. The major competitive edge of the doypacks are its high-gloss, high-quality and pleasant looking finish. Add to the fact that you can save a significant amount of space when shipping plus combined with their recloseable features, doypacks are definitely the best way for packaging your products.

With their zipper closures, stand-up pouches offer the greatest convenience possible. Their bottom gusset allows you to save shelf space by storing them in the garage, closet, kitchen cupboard or refrigerator.

AUTOMATIC BAG FILLING MACHINES FOR DOYPACKS (STAND-UP POUCHES) ARE OFFERED IN THREE MODELS

Swifty Junior pre-made pouch for speeds up to 800 bags per hour

Swifty 1200 pre-made pouch machine for speeds up to 1,800 bags per hour

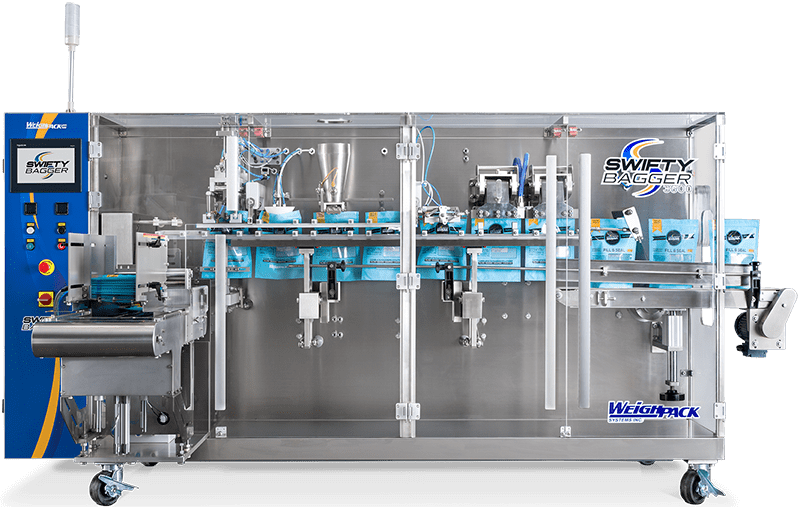

Swifty 3600 pre-made pouch machine for speeds of up to 2,500 bags per hour

COMPACT AND ECONOMICAL SWIFTY

In addition , the ever compact and economical Swifty Junior perfect for small to medium production rates. Its compact footprint and open design makes it easy to set-up, operate and clean. It comes with an easy to adjust bag magazine to ensure consistent output and seals. Built with a highly accessible Lexan doors, cleaning the machine is just a matter of minutes. Its standard features include automatic bag magazine, stainless steel frame, and Omron PLC and touchscreen.

Designed for large bag size requirements and engineered for medium to high level production rates were Swifty 1200 and Swifty 3600. A unique straight-flow design for accessibility, configured to be color-coordinated to your convenience featured to both machine. Furthermore, food safety purposes has easy fill and easy adjust bag magazine Their standard features are an easy-load bag feeder, photo sensor for bag opening detection, and a PLC touchscreen.

Finally, all Swifty Baggers are can also be integrated with any auxiliary filling machines. Therefore, it includes our PrimoCombi, multi-head weigher, PrimoLinear net weigher, and Star Auger filling machine.