We at WeighPack manufacture a wide range of packaging machines and out of these several machineries. We have four product lines that are perfect for packaging and bagging snack food. These are the following snack packaging machines:

Container Indexing Conveyor

VerTek Vertical Form, Fill and Seal series

XPdius vertical bagger

Swifty Bagger automatic bag filling machines

Our container indexing conveyor is built with a heavy-duty stainless steel framed is designed to automatically index, fill and package. A wide variety of products into rigid containers. Such as, cans, jugs, bottles tubs, trays, clamshells, cartons and more.

Engineered to match your specific needs and production requirements, our container indexing conveyor promotes quick changeover and user-friendliness. Some of its standard features include color touchscreen, PLC controls adjustable guide rail, a pneumatic indexing mechanism, A/C variable speed drive and sensors for container positioning.

VERTEK SERIES SNACK PACKAGING MACHINES

Another snack packaging machines are our two vertical form, fill and seal (VFS or VFFS) bagging machines. First up, is the VeTek Vertical Form, Fill and Seal series. This provides high flexibility and ease of use. We have 4 models that can produce vertical pouches or bags. These can be as narrow as 1 inch wide to as much as 24 inches wide.

VerTek 800 can produce pouches of up to 8 inches wide while VerTek 1200 can produce up to 12 inches wide. Both are made with a 304 stainless steel frame for a cleaner and easier maintenance. VerTek 1600 is built with a heavy-duty welded frame that can produce pouches up to 16 inches with an option of a carry handle for added convenience. It is designed for large club size packages. On the other hand, VerTek 2400 is perfect for any bulk packaging application that can produce large pouches up to 24 inches wide. Both models offer low maintenance cost using off-the-shelf parts.

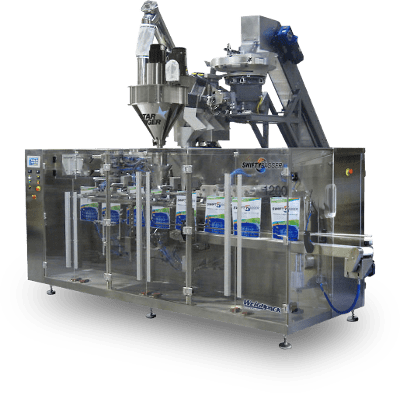

Finally, we have the Swifty Bagger series consisting of three models all designed to automatically open, fill and seal pre-made stand-up pouches. First is the Swifty Junior that is ideal for small to medium production rates producing up to 800 bags per hour. Its standard features include an easy-load bag feeder, photosensor for bag opening detection, and PLC touchscreen. Another is the Swifty 1200 for larger bag size requirements producing as many 1,800 bags per hour. Last is the robust Swifty 3600 with a production speed of 2,500 bags per hour. Both Swifty 1200 & 3600 include standard features like automatic bag magazine, stainless steel frame, and Omron PLC and touchscreen.