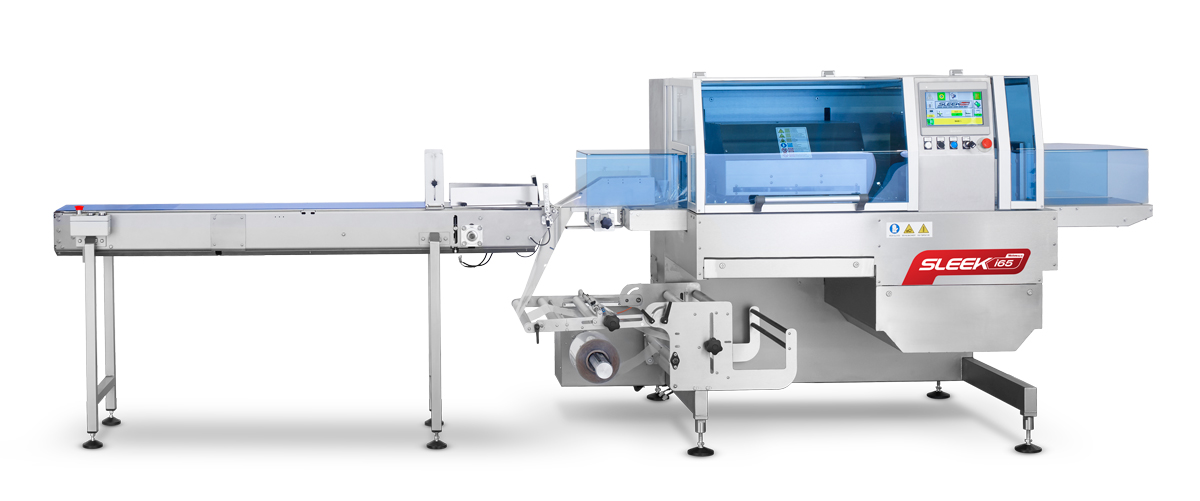

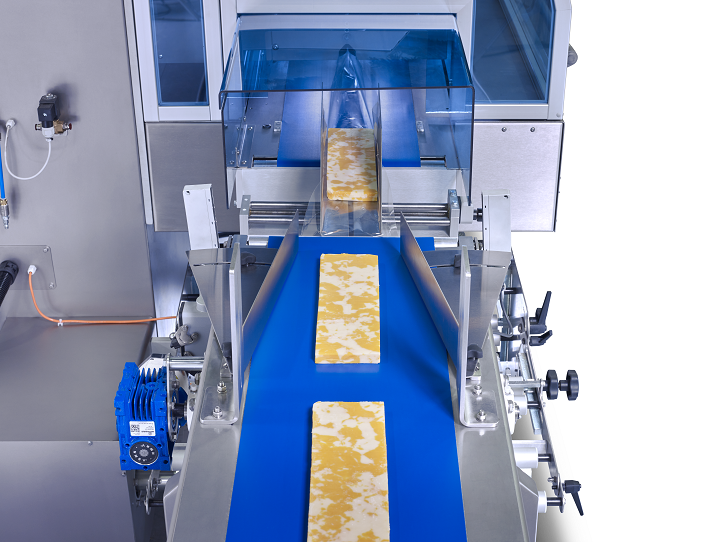

SLEEK F65

HIGH PERFORMANCE

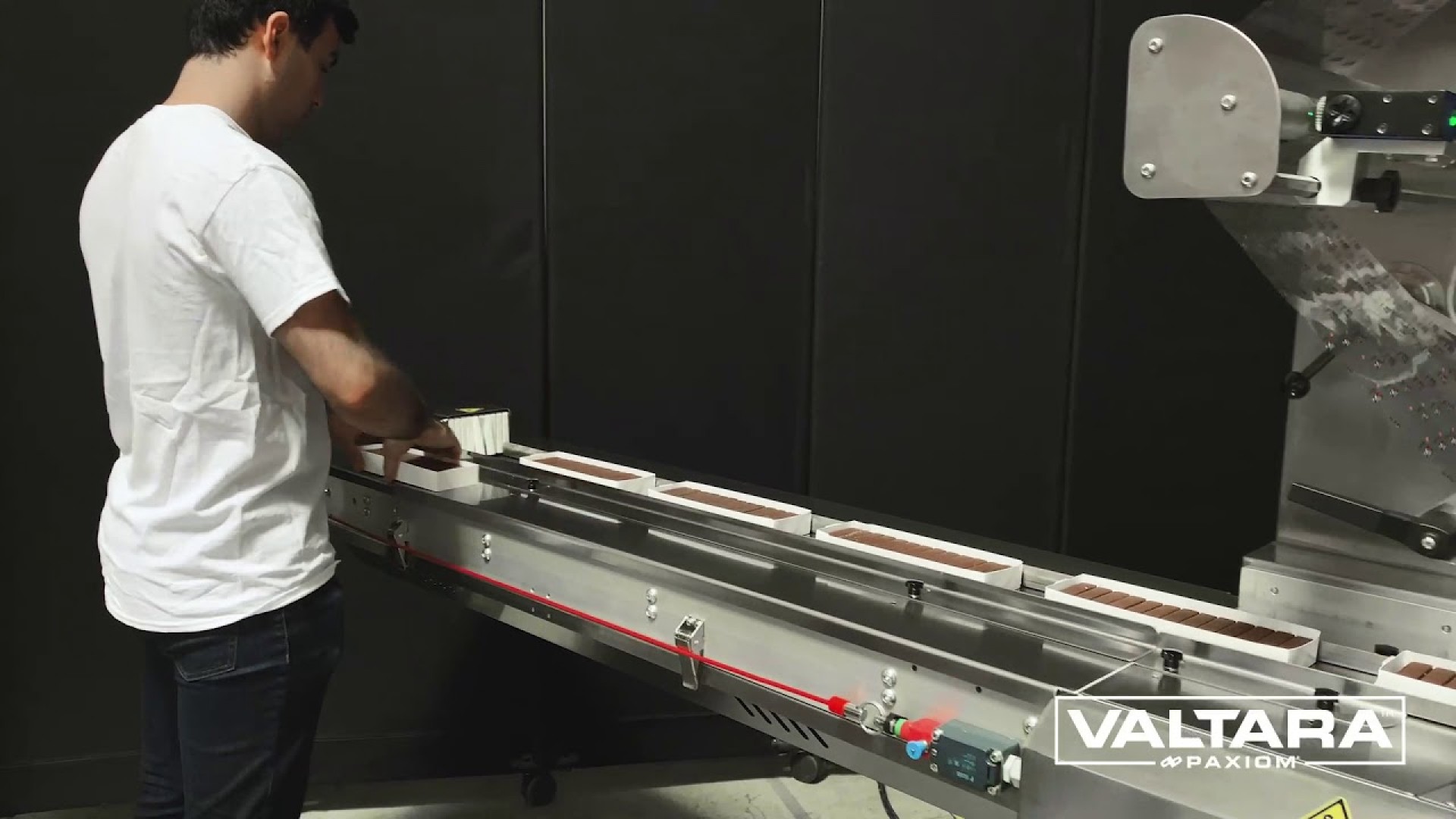

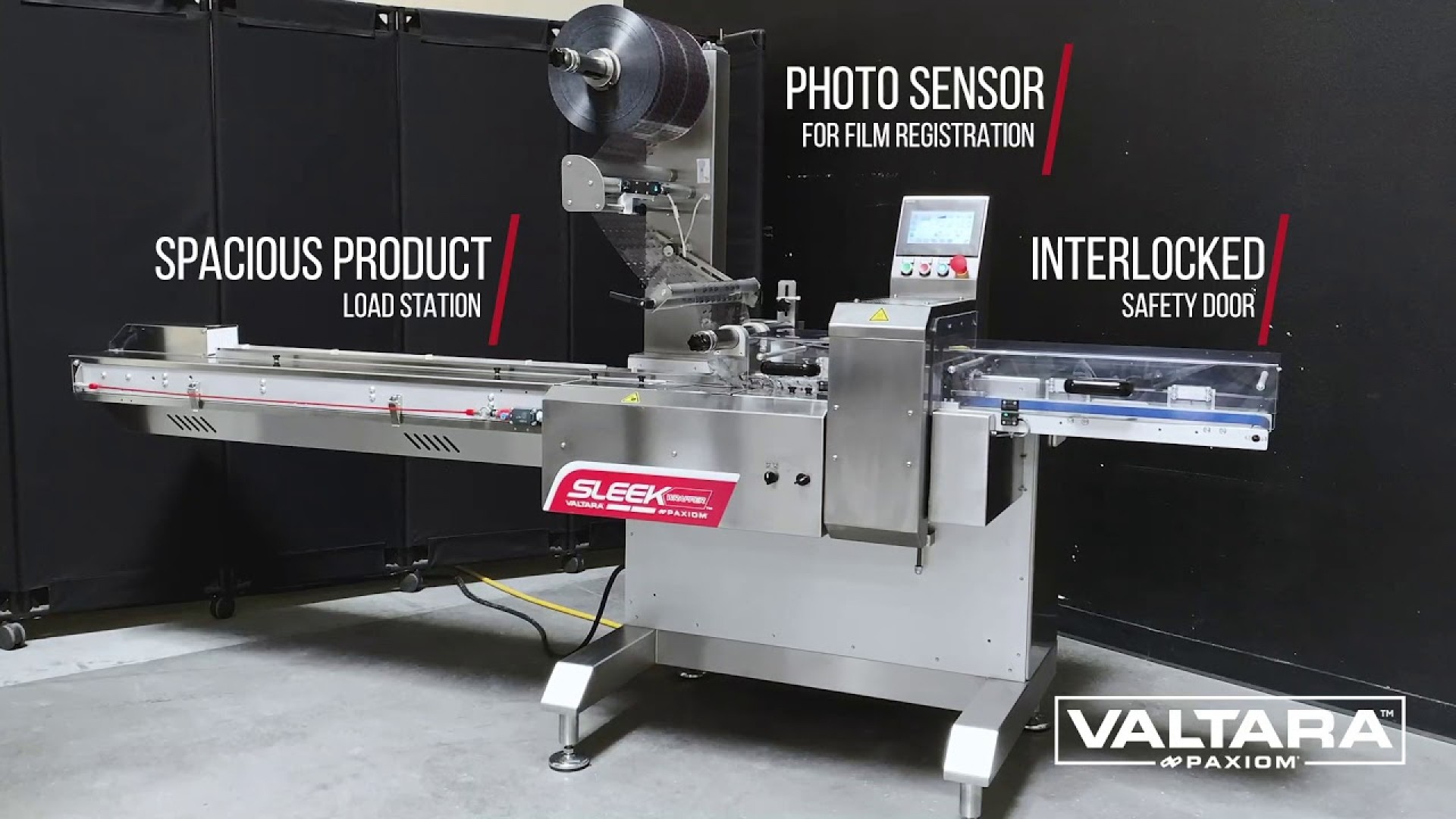

The heavy-duty SleekWrapper 65 horizontal wrapping machine is designed with ith reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 220 packages per minute (subject to jaw configuration and product size) with a large maximum web width of 25.6 inches or 650mm.

The Sleek 65 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek F65 is suited for all industries as your go to high performance flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

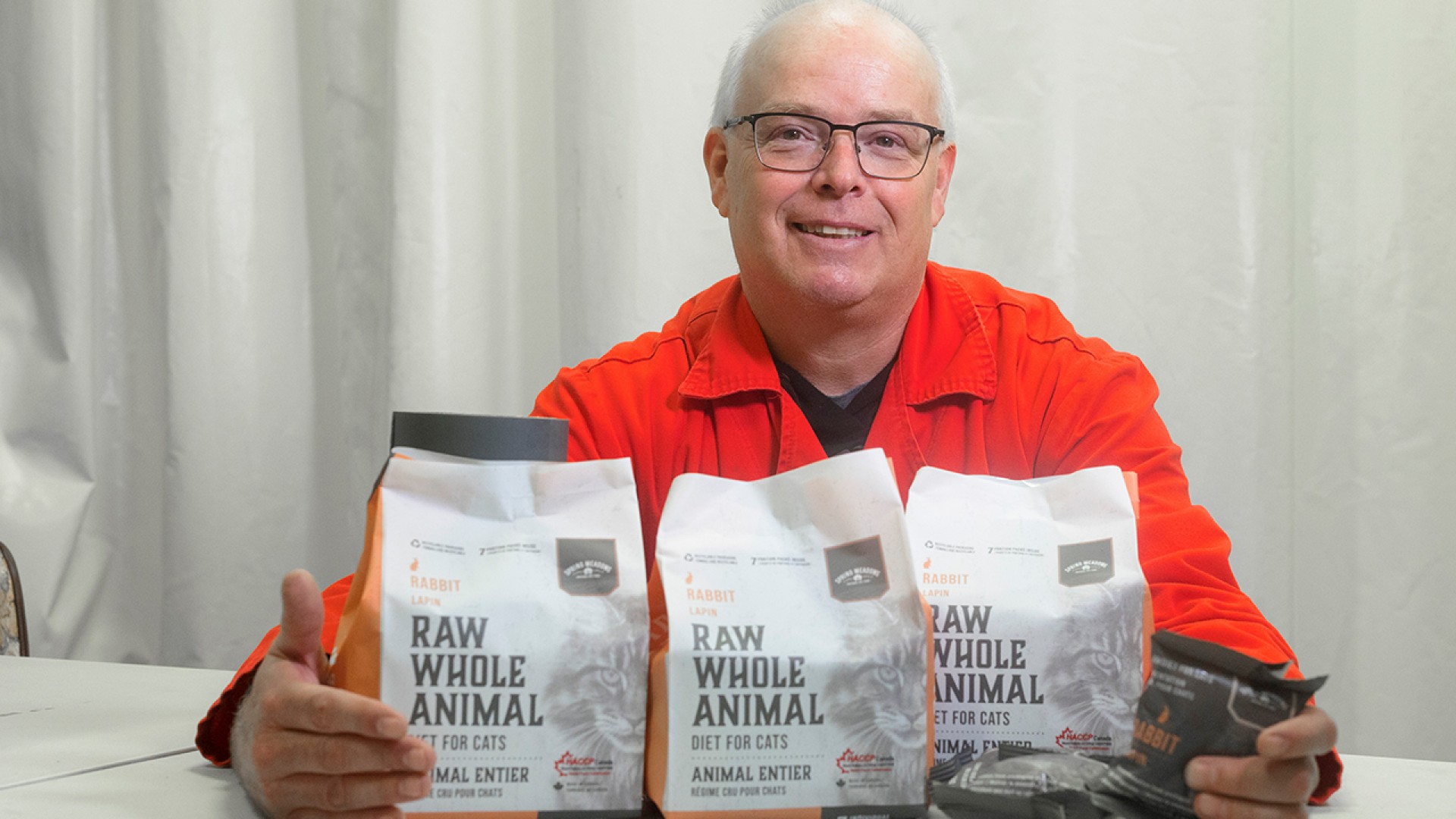

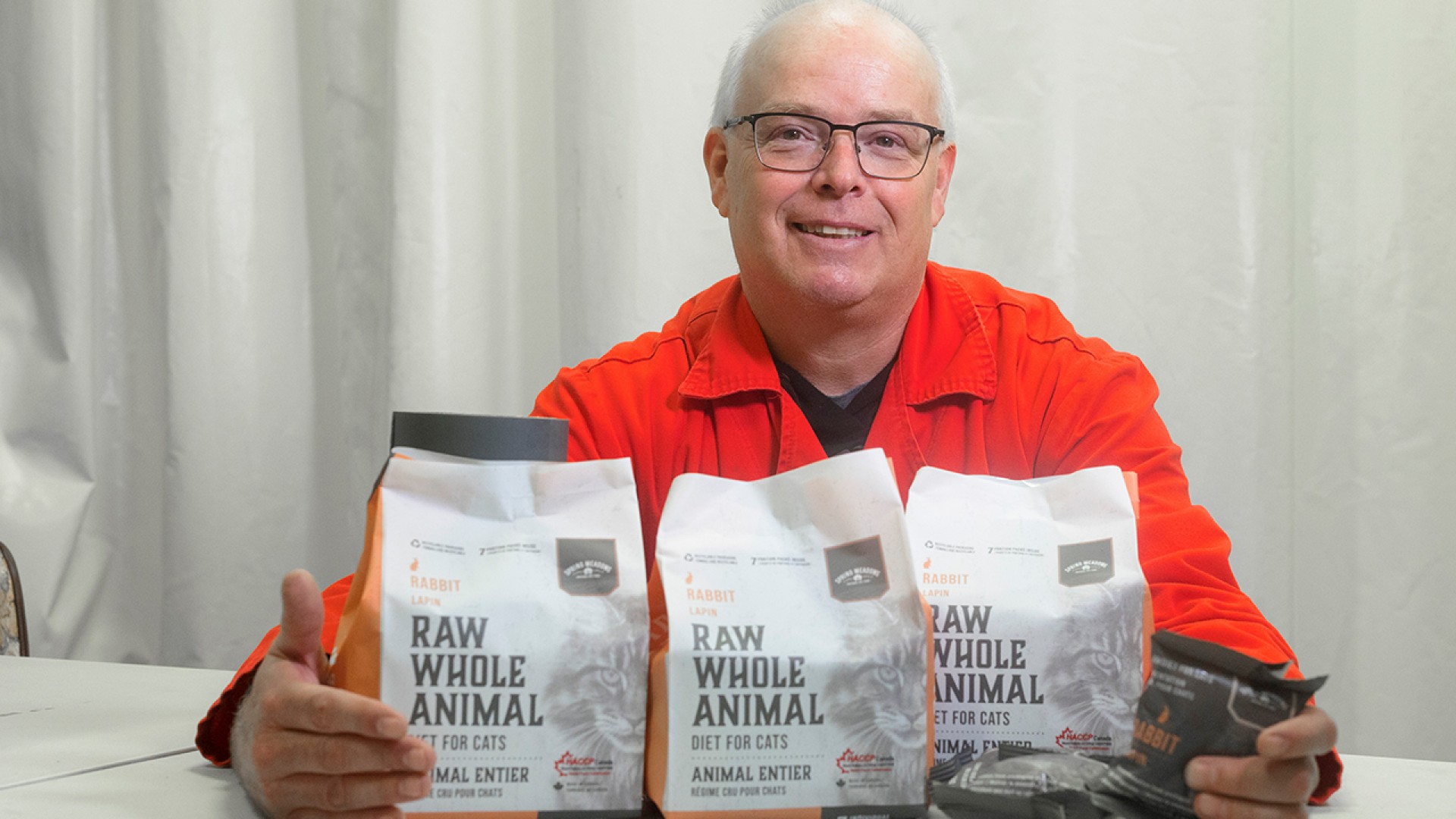

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek F65 is suited for all industries as your go to high performance flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

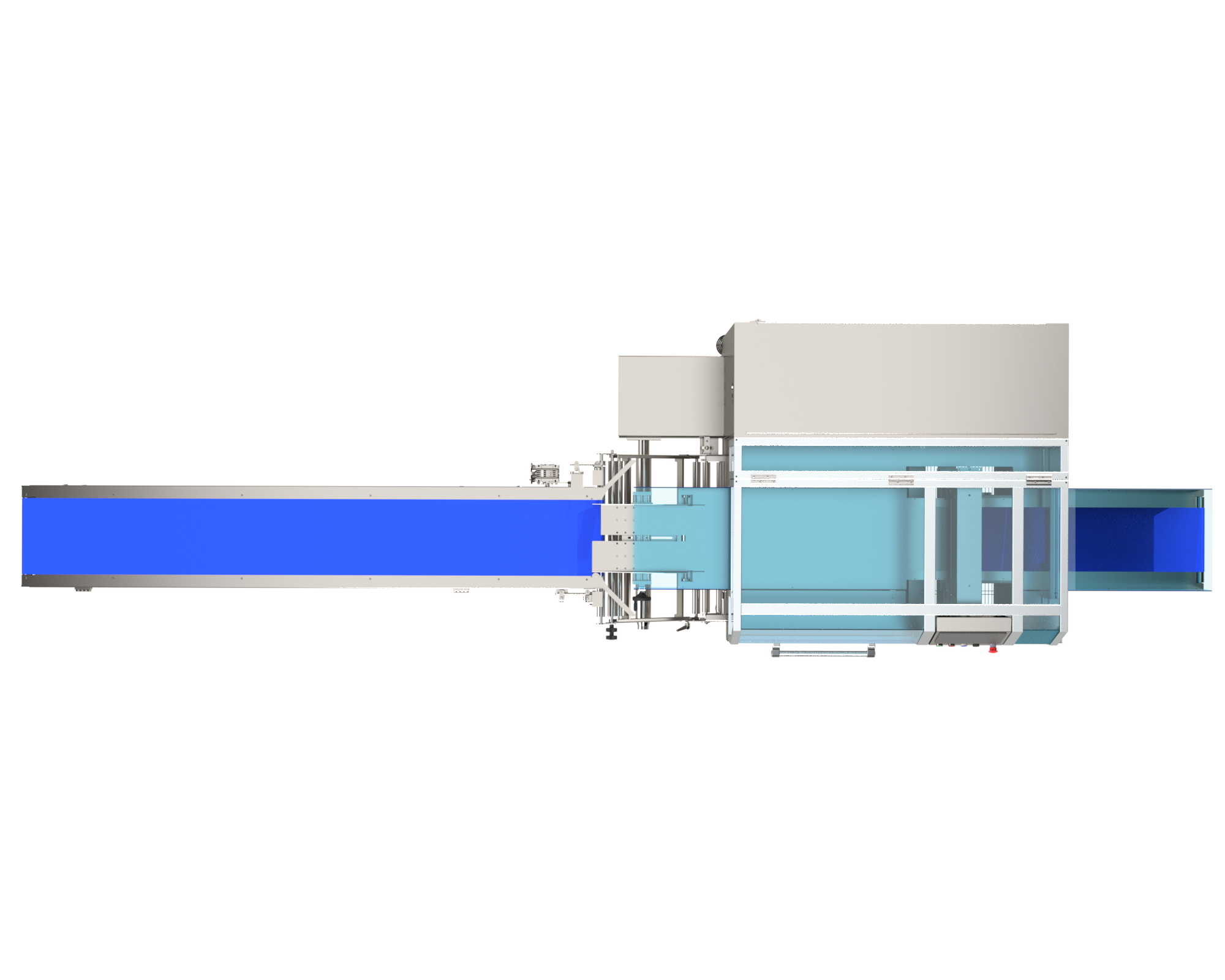

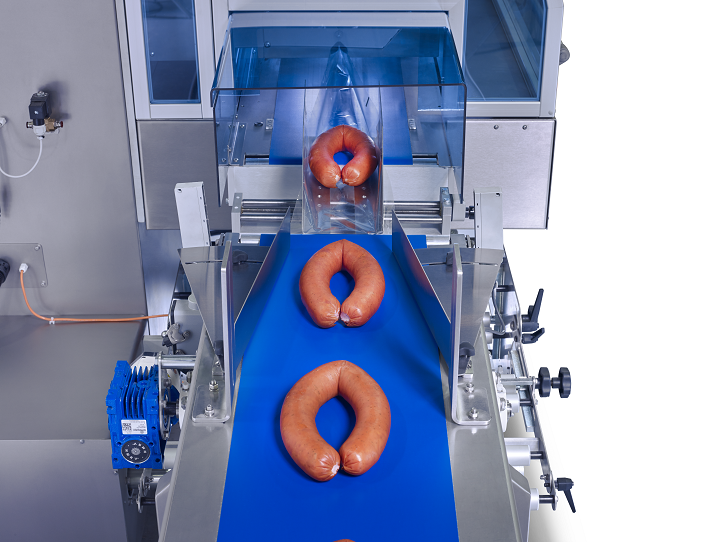

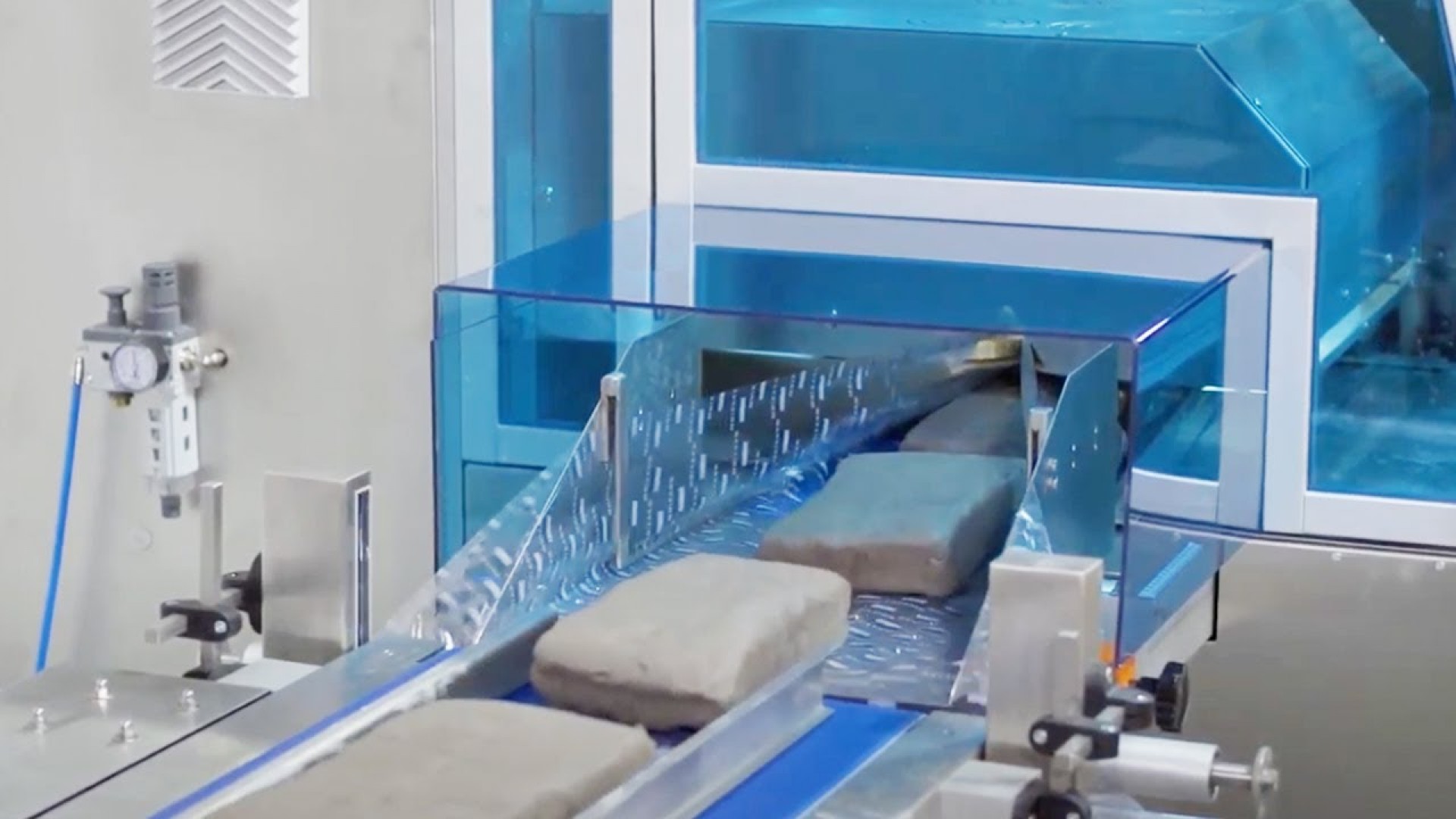

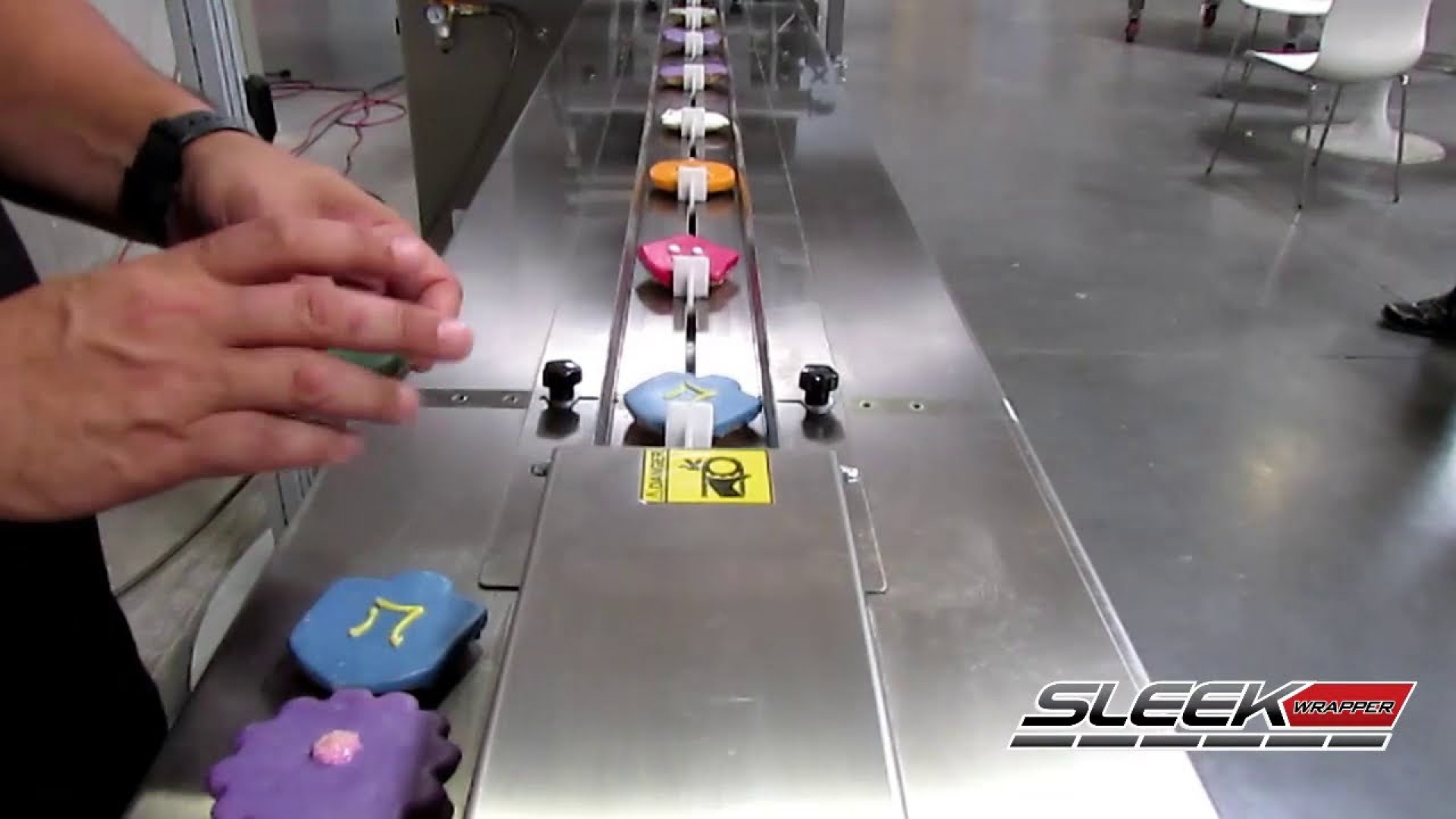

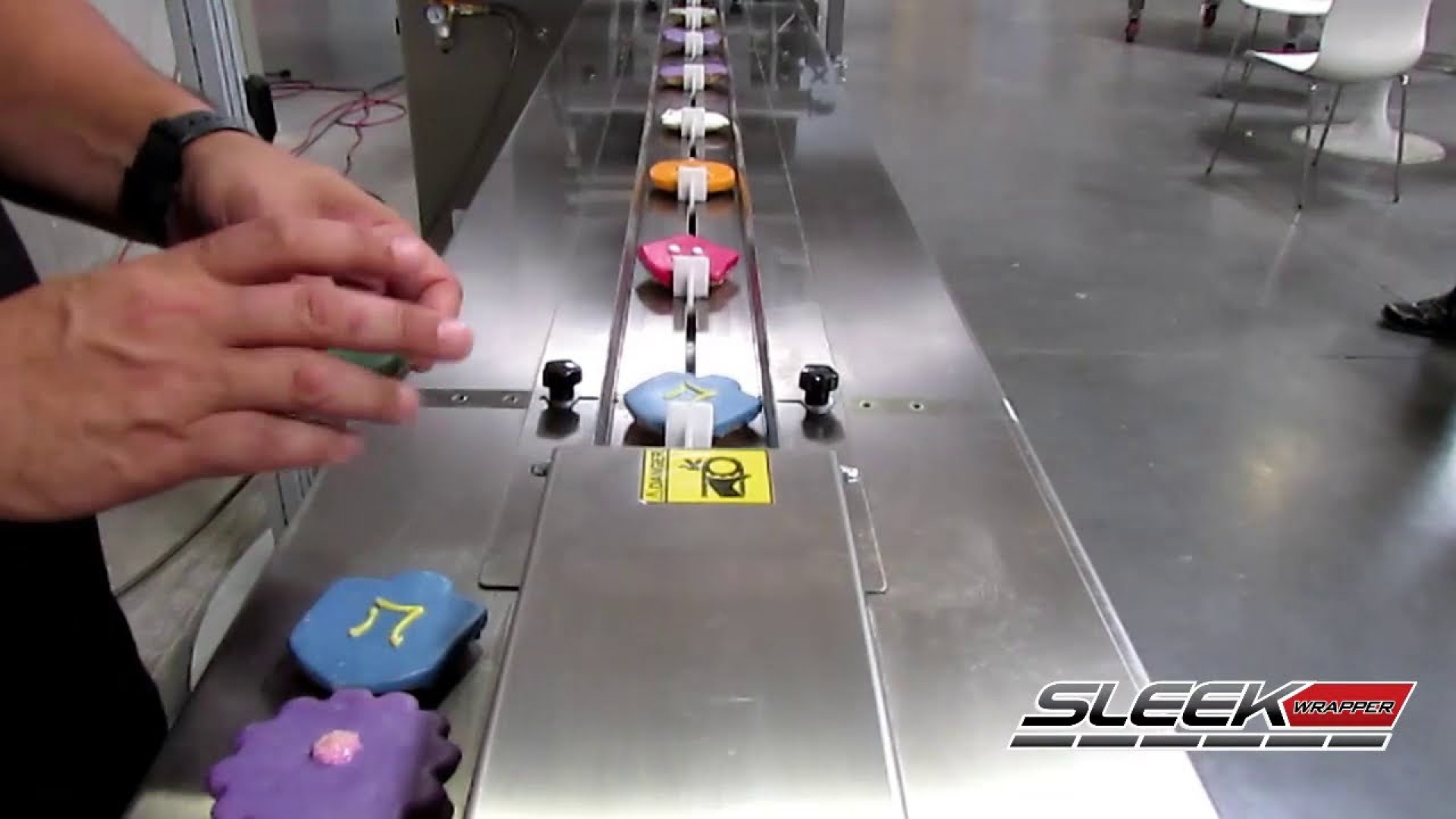

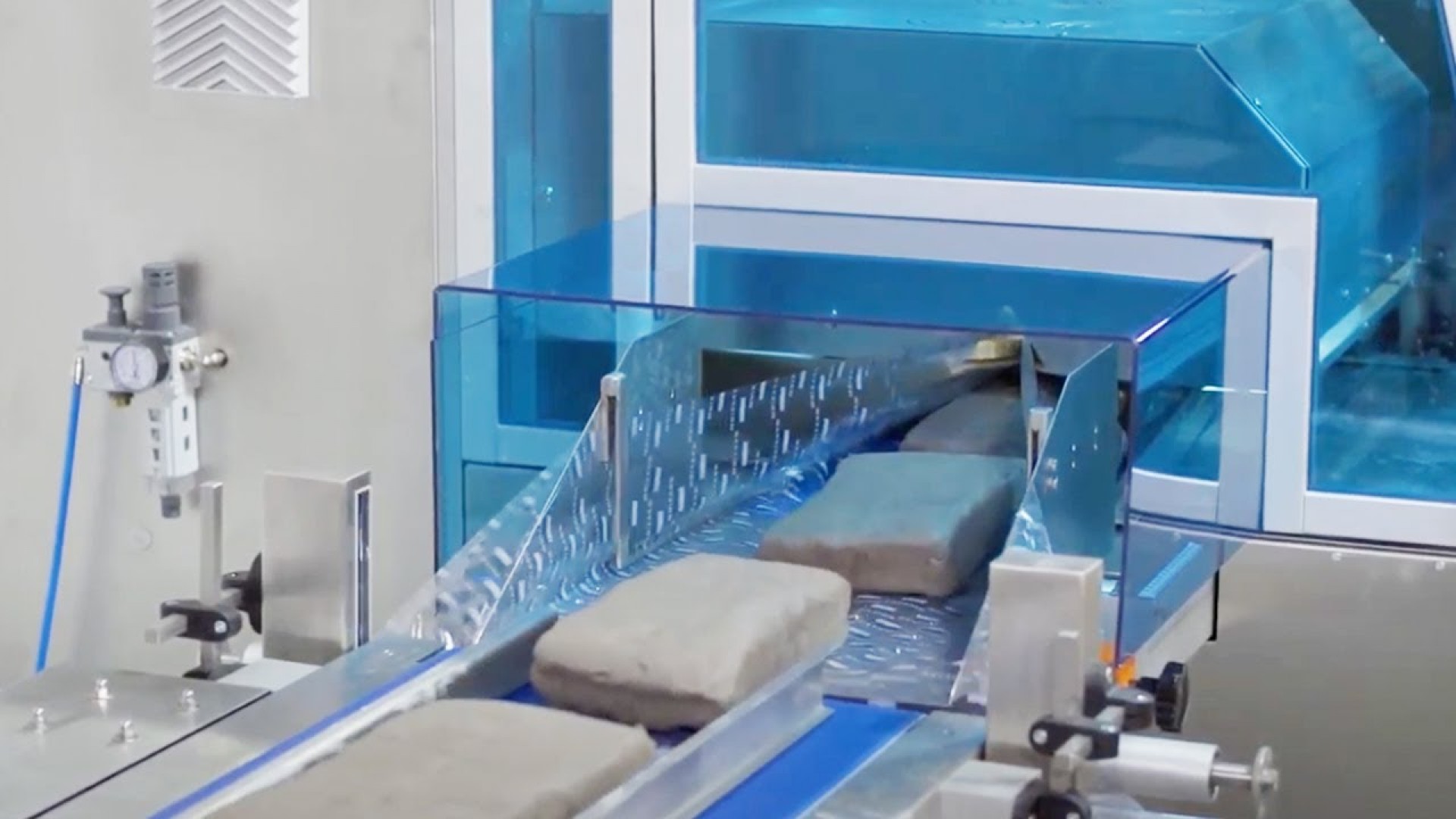

SLEEK I-65

INVERTED FLOW WRAPPING

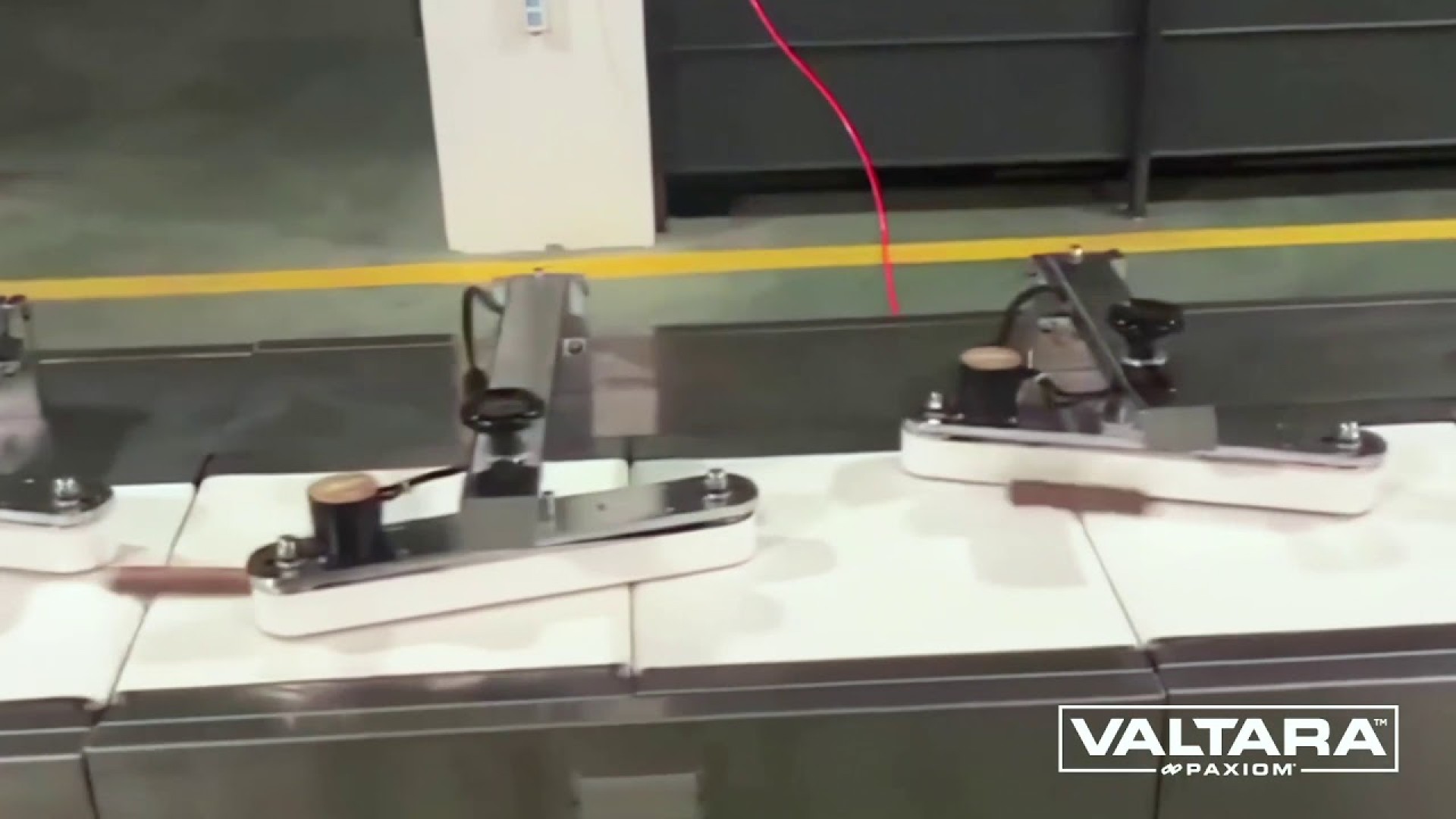

The high-performance SleekWrapper Inverted horizontal wrapping machine designed is designed with ith reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 60 packages per minute with a maximum web width of 25.5 inches or 650mm.

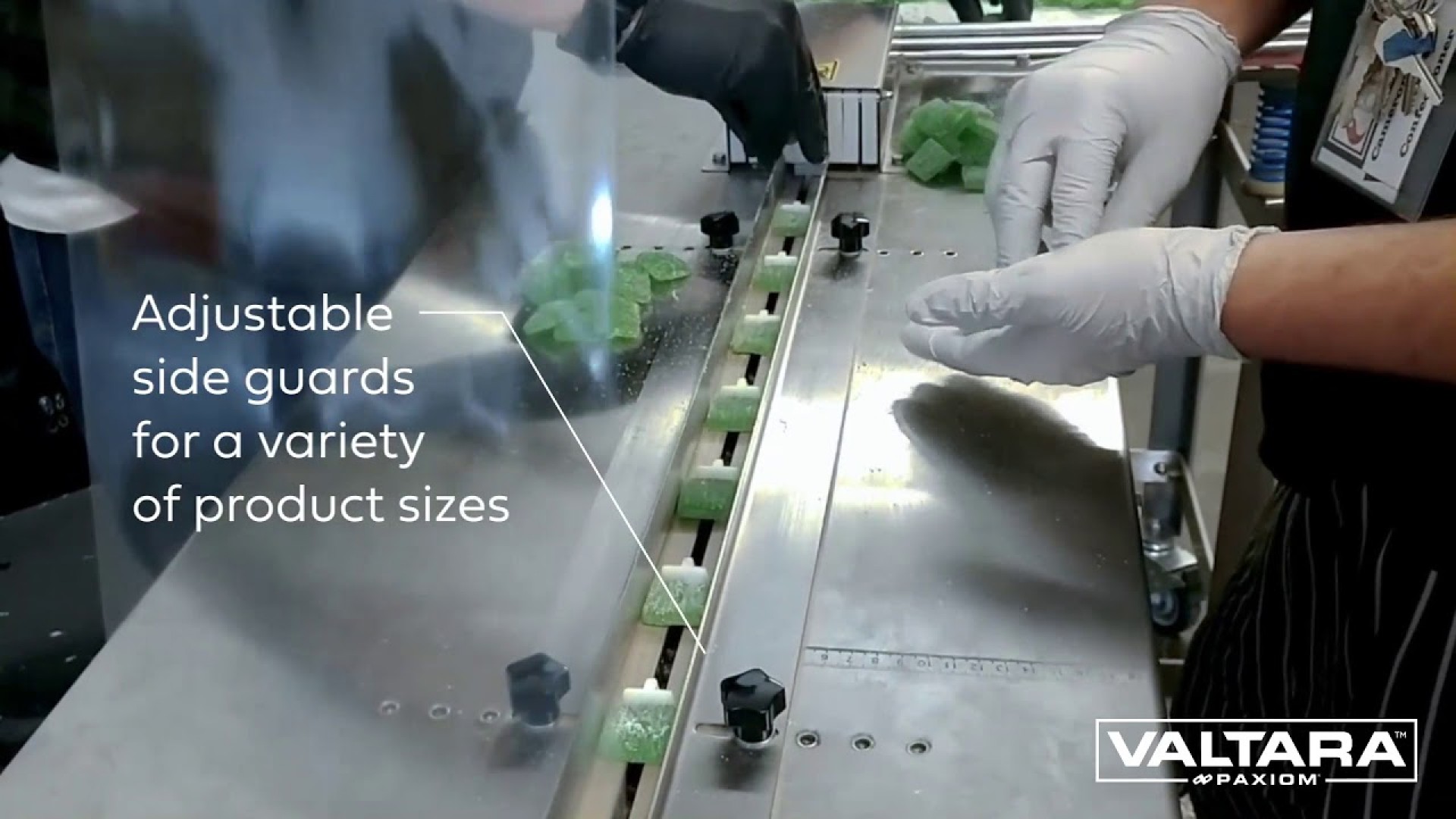

It is ideal for soft or sticky products, multipacks and other products that are difficult to push with the typical lug chain design found on conventional bottom seal flow wrappers. The film is fed from below the product and hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head.

The Sleek Inverted features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

SLEEK 40

The Most Compact Flow Wrapper

The SleekWrapper 40 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 120 packages per minute with a maximum web width of 15.5 inches or 400mm. The Sleek 40 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Our machines come standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

*Rates subject to package style, type and size

Our Sleek 40 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek 40 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

SLEEK 45

HIGH SPEED

The high-speed SleekWrapper 45 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 160 packages per minute (subject to jaw configuration and product size) with a maximum web width of 18 inches or 450mm.

The Sleek 45 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Multiple servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Videos

Videos

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

Our Sleek 45 is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek 45 is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

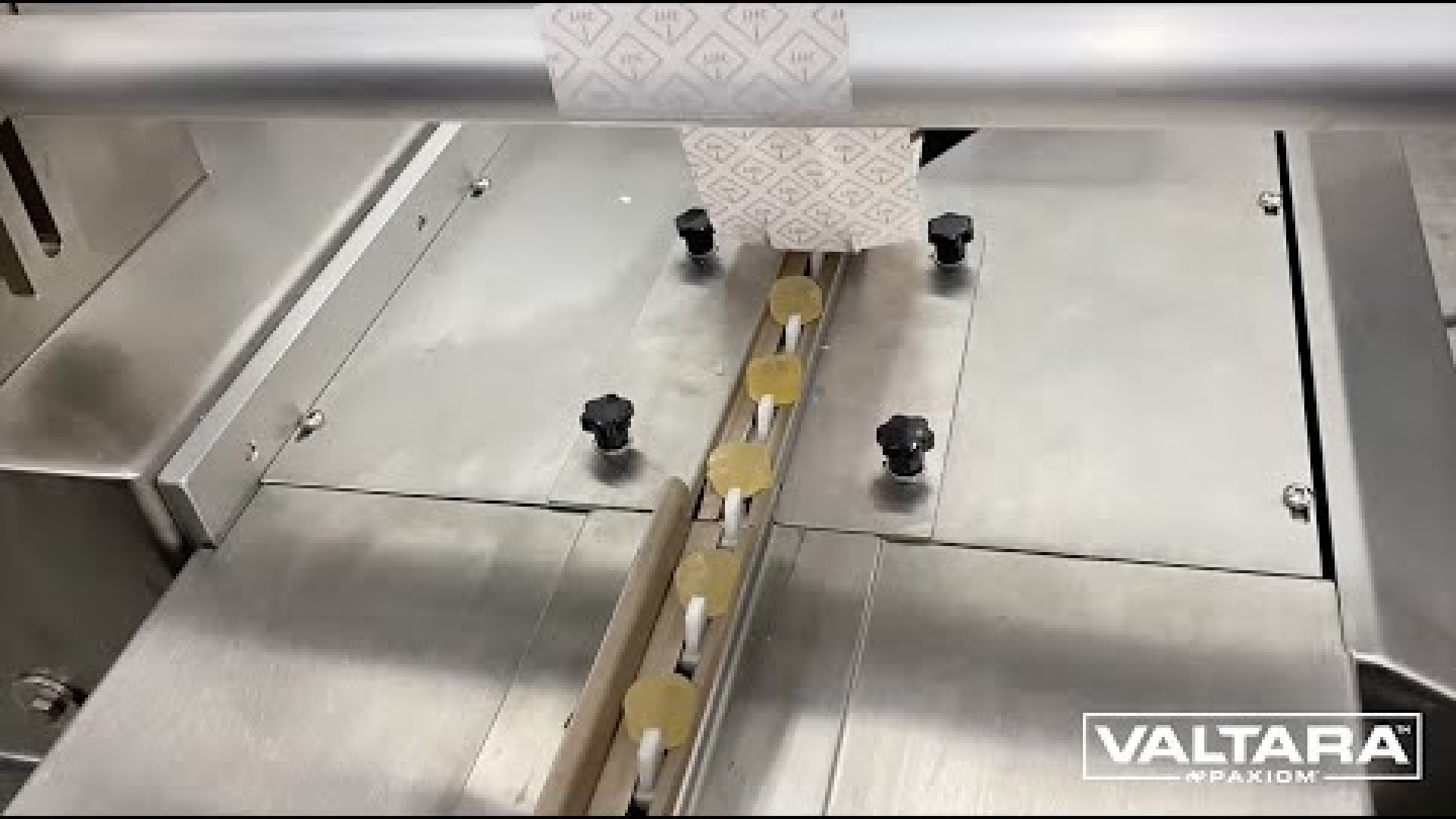

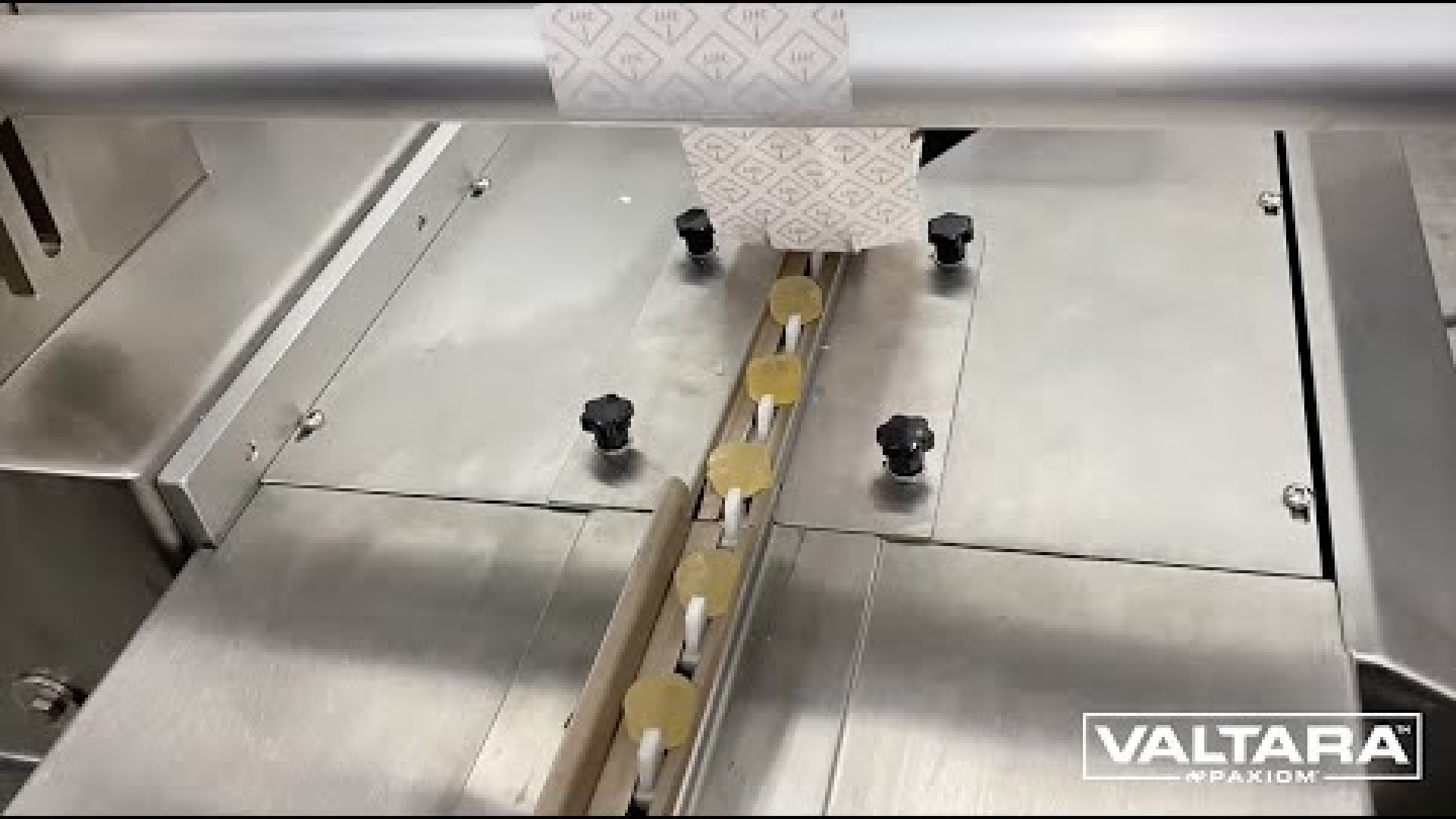

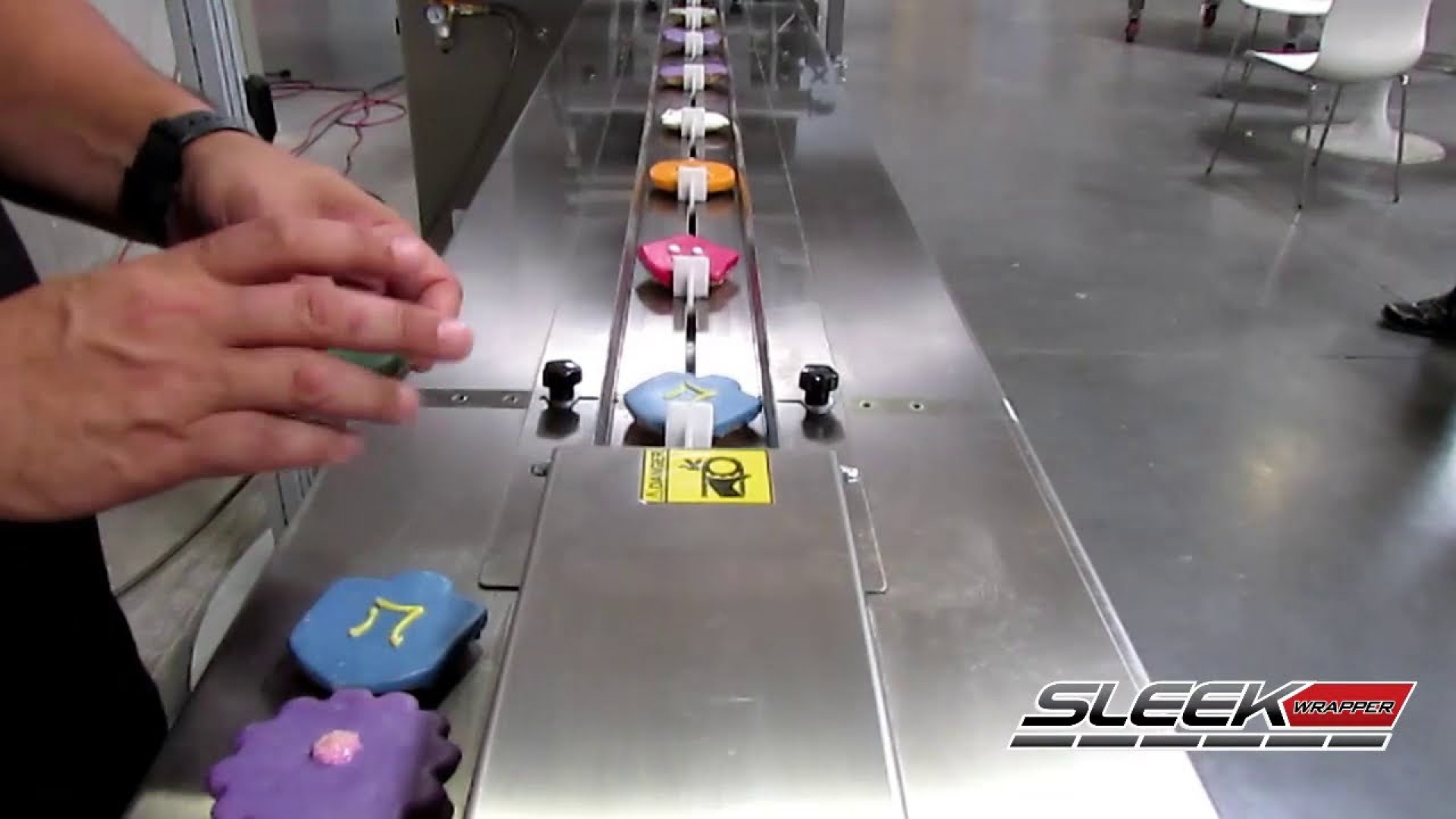

SLEEK HSA

Chicane Product Aligner

The SleekWrapper HSA with chicane product aligner high-speed flow wrapper is engineered to accurately load, align and wrap product according to your project specifications. This reliable system is perfect for wrapping candies, chocolates and baked goods such as cookies and brownies while remaining easy to operate and maintain.

Standard features include a photoelectric automatic detection and servo dosing system, stainless steel frame construction and a 10-inch touchscreen. A second film roll can be added upon request.

Videos

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

Our Sleek HSA is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek HSA is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BREEZY WRAPPER

Horizonal & Vertical Bagging Machine

In the vertical position, it is perfect for automatic bagging and product loading; In the horizontal position, it is perfect for products requiring overwrapping such as trays and containers.

Standard features include a unique length detection sensor and operational logic that adjusts the bag film to the length of the product during each cycle and creates the bag accordingly. The benefit to the user is material cost savings and the ability to fill products that vary in length and bulk density.

This compact automatic bagging machine provides a quick return on investment as productivity rapidly increases, product waste rapidly decreases and labor savings are realized.

Videos

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

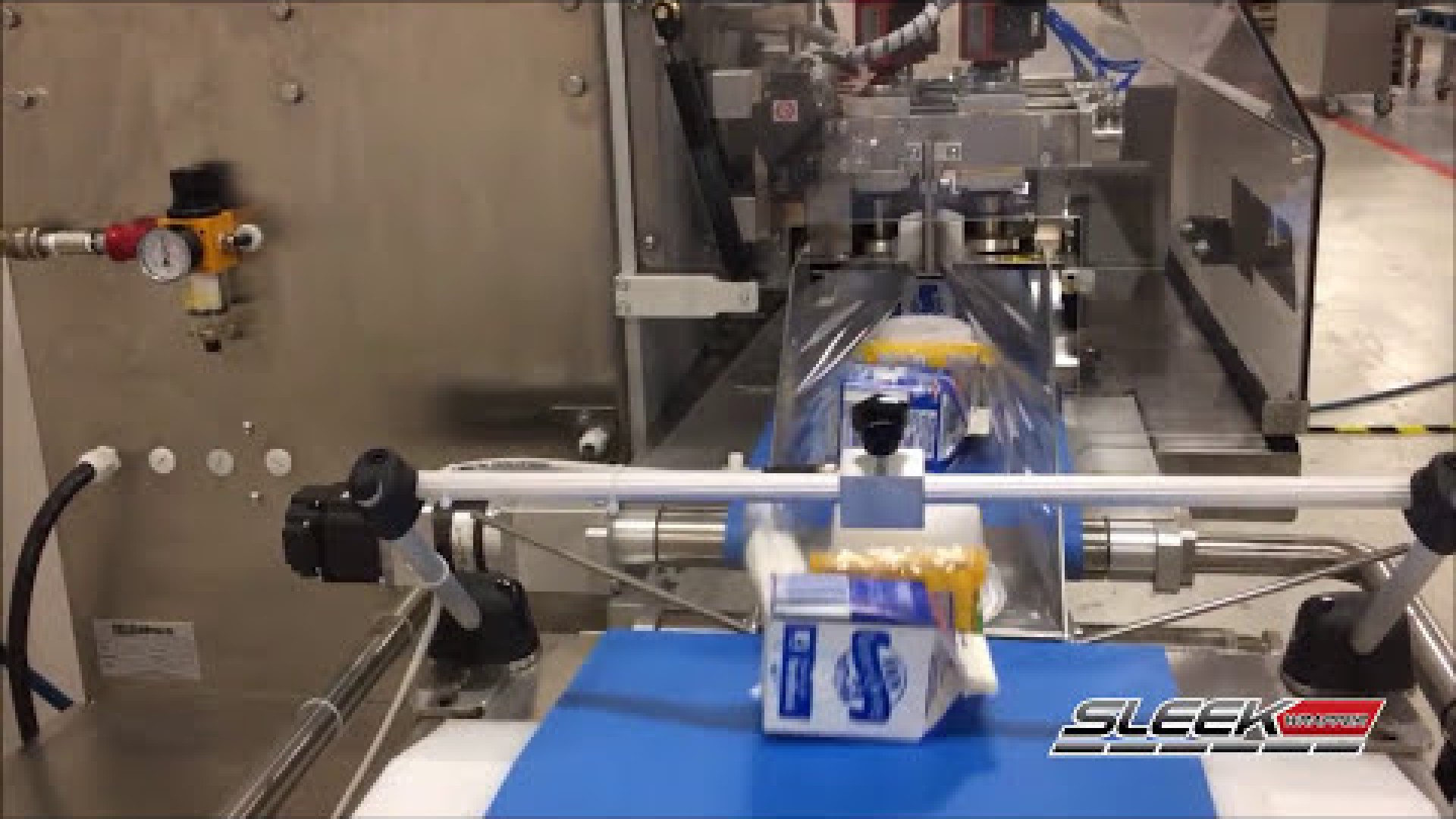

Robotic Loading

Precise Product Placement

We can custom engineer an automatic loading system for your flow wrapping process using one of our PKR pick and place systems.

We can design your system using either our Delta, Gantry or SCARA robot platform and precisely place your product for loading onto the conveyor of one of our flow wrappers or onto your existing flow wrapping machine.

This robotic loading system eliminates the traditional repetitive motion stations, reducing overhead and risky labor practices while increasing efficiencies and throughput.

Our Robotic Loading system is suited for all industries as your go to precise product placement machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Ideal Markets

Our Robotic Loading system is suited for all industries as your go to precise product placement machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

SLEEK F65

High Performance

The heavy-duty SleekWrapper 65 horizontal wrapping machine is designed with ith reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 220 packages per minute (subject to jaw configuration and product size) with a large maximum web width of 25.6 inches or 650mm.

The Sleek 65 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek F65 is suited for all industries as your go to high performance flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek F65 is suited for all industries as your go to high performance flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

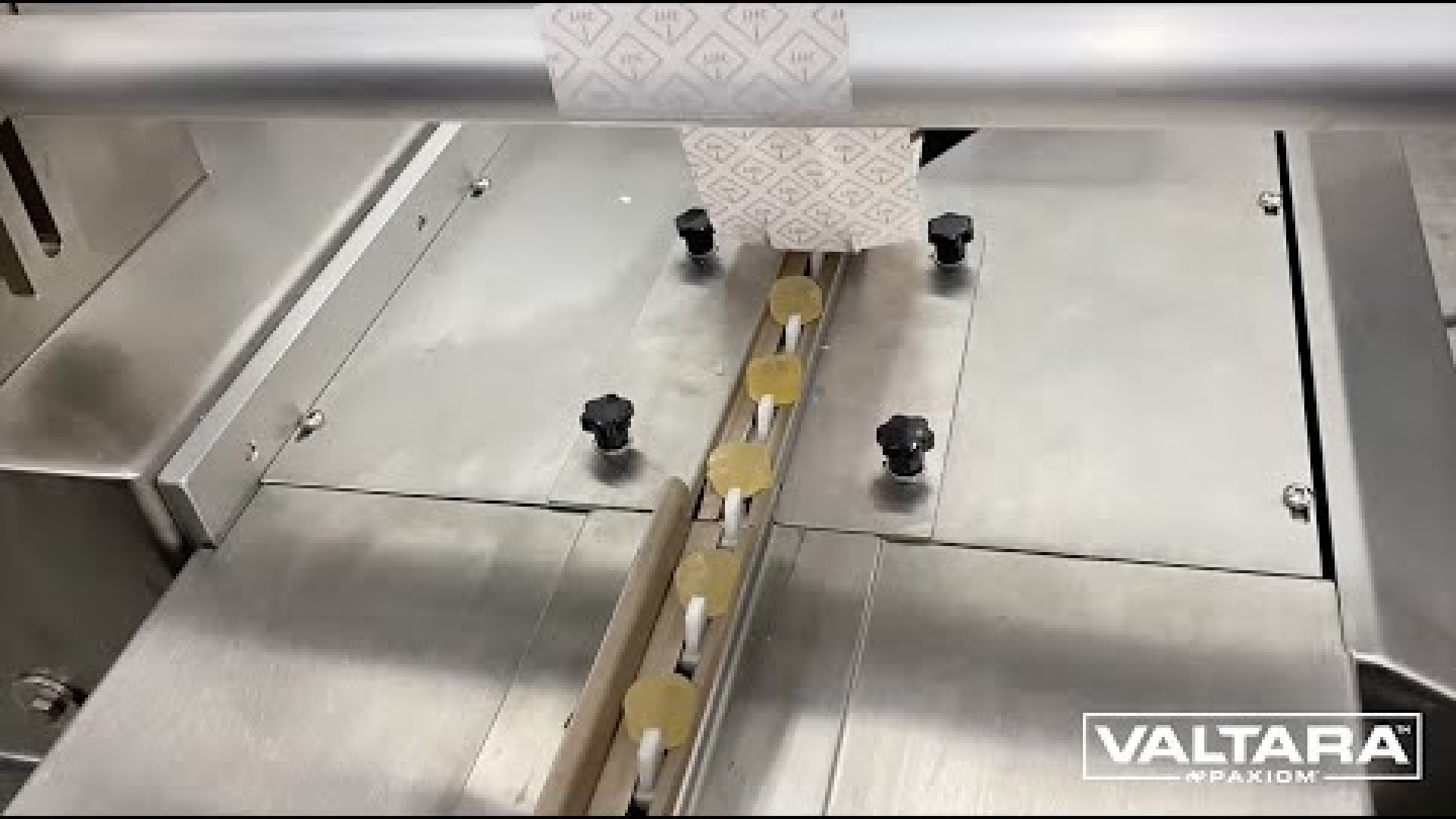

SLEEK I-65

Inverted Flow Wrapping

Videos

The high-performance SleekWrapper Inverted horizontal wrapping machine designed is designed with ith reliability, simplicity and serviceability in mind. Built for a 24/7 environment, this machine will produce up to 60 packages per minute with a maximum web width of 25.5 inches or 650mm.

It is ideal for soft or sticky products, multipacks and other products that are difficult to push with the typical lug chain design found on conventional bottom seal flow wrappers. The film is fed from below the product and hard-to-handle products are securely carried on top of the packaging film from the former through to the cutting head.

The Sleek Inverted features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Five servo-driven motors assure precise positioning with smooth acceleration and deceleration.

This machine comes standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo, driven by 3 servo motors

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film roll holder

- Powered film unwind

- Color touchscreen HMI and OMRON PLC

- Preprogrammed controls for up to 100 recipes

- HMI integrated temperature control

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek I-65 is suited for all industries as your go to inverted flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SLEEK 40

The Most Compact Flow Wrapper

Videos

The SleekWrapper 40 horizontal wrapping machine is designed with reliability, simplicity and serviceability in mind. This machine will produce up to 120 packages per minute with a maximum web width of 15.5 inches or 400mm. The Sleek 40 features quick, easy changeover and adjustment that minimizes product and film waste and reduces maintenance costs. Four servo-driven motors assure precise positioning with smooth acceleration and deceleration.

Our machines come standard with stainless steel frame construction, user-friendly color touchscreen, automatic open/close rotary fin wheel assembly, rotary seal jaws with jam detecting logic and the ability to preprogram and store product settings.

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

*Rates subject to package style, type and size

Our Sleek 40 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

MAX MECHANICAL RATES (NO PRODUCT)

1-up jaw: 50 per minute

2-up jaw: 80 per minute

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek 40 is suited for all industries as your go to bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SLEEK 45

High Speed

Videos

The Swifty Junior pouch filling machine automatically opens, fills and seals premade stand-up pouches (SUP, SURP, DOY) in one process, making it easy to use and easy to integrate with multi-head weighing, net weighing and auger filling machines.

The Swifty Junior is extremely compact requiring only ten square feet of floor space and is perfect for small to medium production rates of up to 900 bags per hour.

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

Our Sleek 45 is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Stainless steel frame construction

- Full servo-driven by 3 servo motors

- Belt Driven

- Infeed conveyor with snap-in pushers for fast changeovers

- Cantilevered single film holder

- Color touch screen HMI and Mitsubishi PLC

- Pre-programmable controls for up to 100 recipes

- Auto open / close rotary fin wheel assembly when machine stops

- Temperature control

- Rotary seal jaws

- Automatic synchronization of crimper after jams

- Optional No Product / No Bag

- Optional No Gap / No Seal for misplaced products

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek 45 is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

SLEEK HSA

Chicane Product Aligner

Videos

The SleekWrapper HSA with chicane product aligner high-speed flow wrapper is engineered to accurately load, align and wrap product according to your project specifications. This reliable system is perfect for wrapping candies, chocolates and baked goods such as cookies and brownies while remaining easy to operate and maintain.

Standard features include a photoelectric automatic detection and servo dosing system, stainless steel frame construction and a 10-inch touchscreen. A second film roll can be added upon request.

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

Our Sleek HSA is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Advanced full servo motor and driver control system for easy maintenance, low failure rate and stable performance.

- Large color touch screen and PLC controls

- Equipped with photoelectric automatic detection and servo dosing system.

- With automatic acceleration and deceleration, automatic fill function, accurate positioning, no empty package.

- Stainless steel sheet metal exterior – 304

- Integrated system design

- Second film roll support

- Automatic film splicing

*Rates subject to package style, type and size

- Ideal Markets

Our Sleek HSA is suited for all industries as your go to high speed flow wrapping machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

BREEZY BAGGER

Horizonal & Vertical Bagging Machine

In the vertical position, it is perfect for automatic bagging and product loading.

In the horizontal position, it is perfect for products requiring overwrapping such as trays and containers.

Standard features include a unique length detection sensor and operational logic that adjusts the bag film to the length of the product during each cycle and creates the bag accordingly. The benefit to the user is material cost savings and the ability to fill products that vary in length and bulk density.

This compact automatic bagging machine provides a quick return on investment as productivity rapidly increases, product waste rapidly decreases and labor savings are realized.

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Omron PID temperature controller

- Color touchscreen

- SMC vacuum generator

- Quick bag loading station with vacuum mechanism

- No bag—no fill sensor

- 304 stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Swifty Bagger Mini is suited for all industries as your go-to compact pouch filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

ROBOTIC LOADING

Precise Product Placement

We can custom engineer an automatic loading system for your flow wrapping process using one of our PKR pick and place systems.

We can design your system using either our Delta, Gantry or SCARA robot platform and precisely place your product for loading onto the conveyor of one of our flow wrappers or onto your existing flow wrapping machine.

This robotic loading system eliminates the traditional repetitive motion stations, reducing overhead and risky labor practices while increasing efficiencies and throughput.

Our Robotic Loading system is suited for all industries as your go to precise product placement machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Ideal Markets

Our Robotic Loading system is suited for all industries as your go to precise product placement machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.