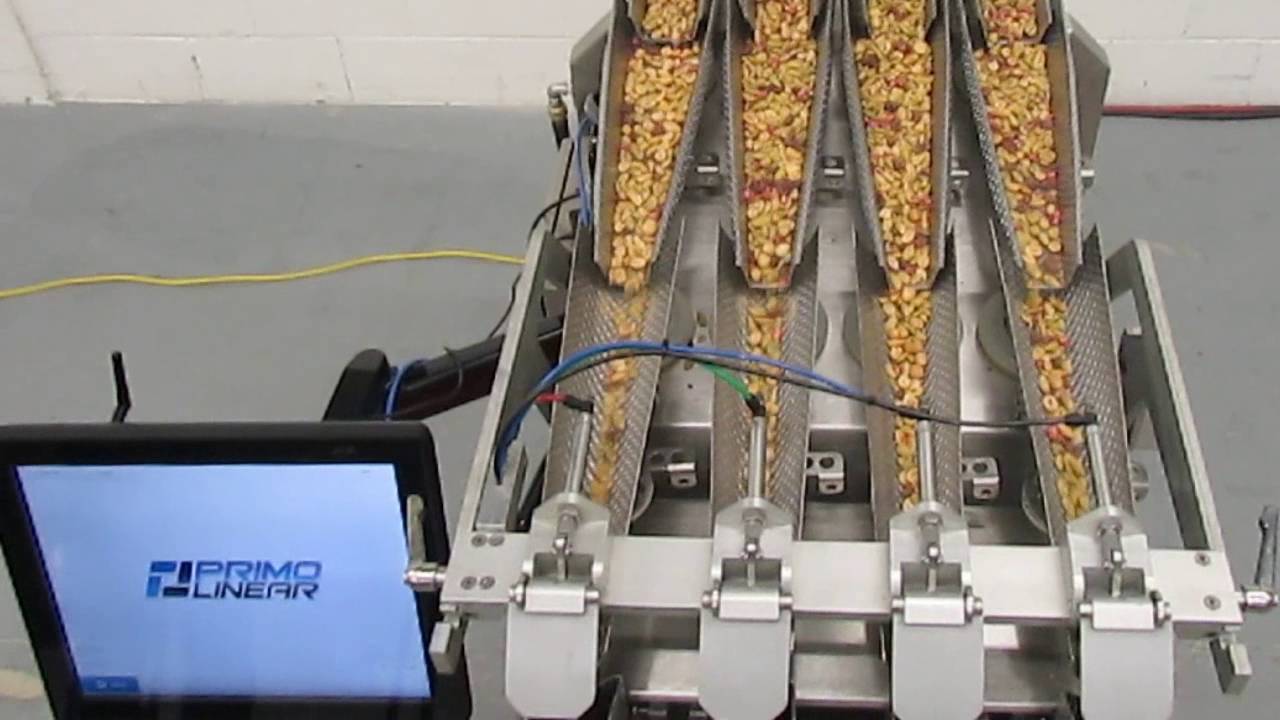

V-MINI WEIGH FILLER

FOR MINOR INGREDIENT FILLING

Weigh filler is ideal for accurately dispensing ingredients and small weighments.

Very accurate, it can dispense weights as small as one gram and reads in 1/100th of gram increments.

Typical applications include nuts, dried fruits, seasonings, confections, chocolate, spices, herbs diced meats, cheese and pharmaceuticals.

Videos

Features

- Digital independent vibrator speed control

- Adjustable electronic filtering

- Multi-speed control

- 304 stainless steel contact parts

- 304 stainless frame

- V-shaped dribble pan

- Compact design

- Too-less removable buckets

- Too-less removable funnel

- PC controls with Windows platform

*Rates subject to package style, type and size

Our V-Mini is suited for all industries as your go to ingredient filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Digital independent vibrator speed control

- Adjustable electronic filtering

- Multi-speed control

- 304 stainless steel contact parts

- 304 stainless frame

- V-shaped dribble pan

- Compact design

- Too-less removable buckets

- Too-less removable funnel

- PC controls with Windows platform

*Rates subject to package style, type and size

- Ideal Markets

Our V-Mini is suited for all industries as your go to ingredient filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

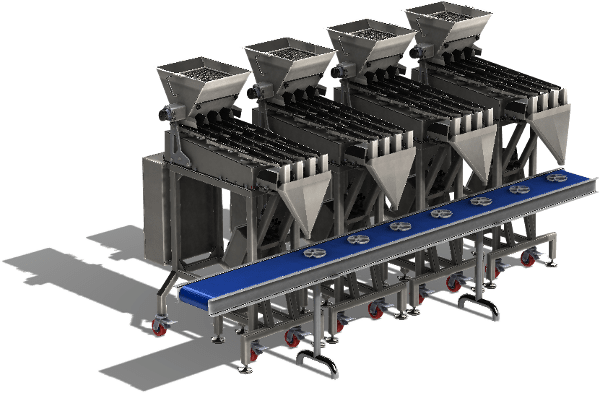

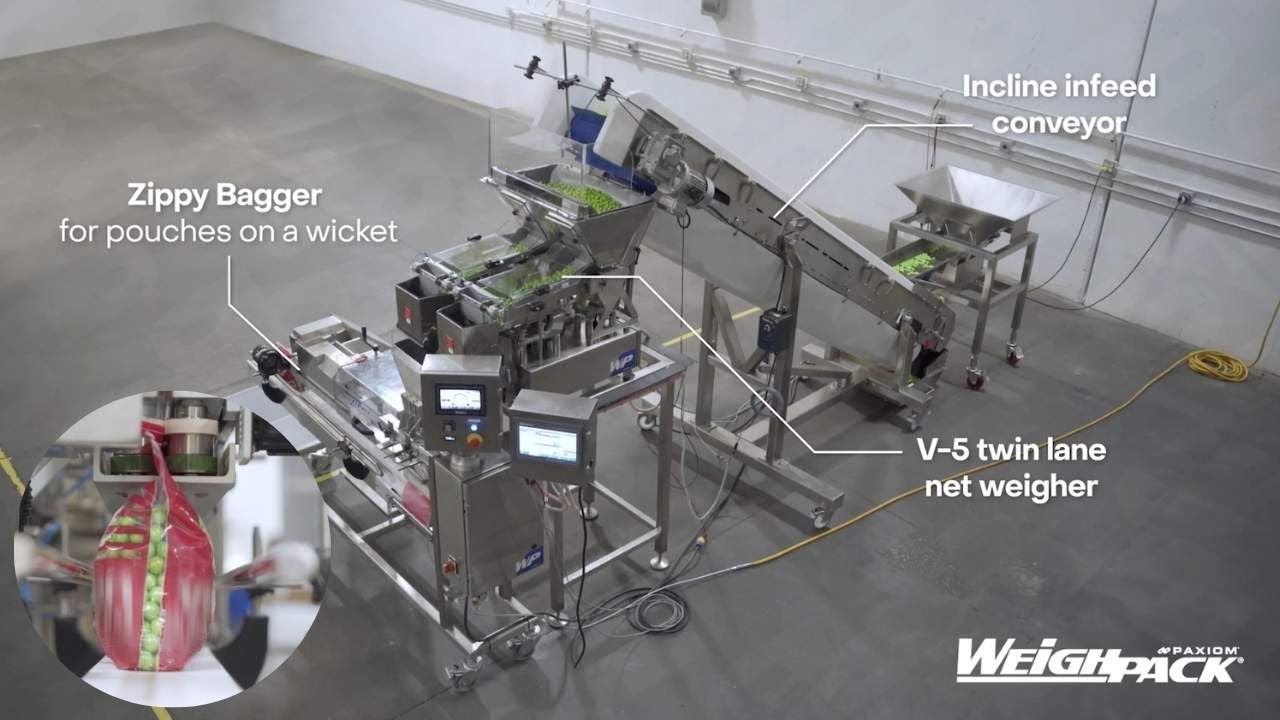

V-5/10 WEIGH FILLER

COMPACT AND EASY TO USE

Automatic weigh filling machine is designed to accurately dispense and fill a wide range of products into bags, cartons, trays, boxes, jars and containers.

The PrimoLinear will accurately weigh, dispense and package nuts, snack foods, candy, hardware, frozen foods, vegetables, fruits, meat, poultry, ingredients, spices, coffee, powders, granules, pet food and much more.

Designed for long term use and dependability the PrimoLinear includes a stainless steel frame, tool-less tilting hopper that requires no change-over when running multiple applications; tool-less removable contact parts, and standardized components that reduce maintenance costs.

Videos

Features

- 5 and 10L weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

Our V5 Net Weigher is suited for all industries as your go to net weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 5 and 10L weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

- Ideal Markets

Our V5 Net Weigher is suited for all industries as your go to net weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

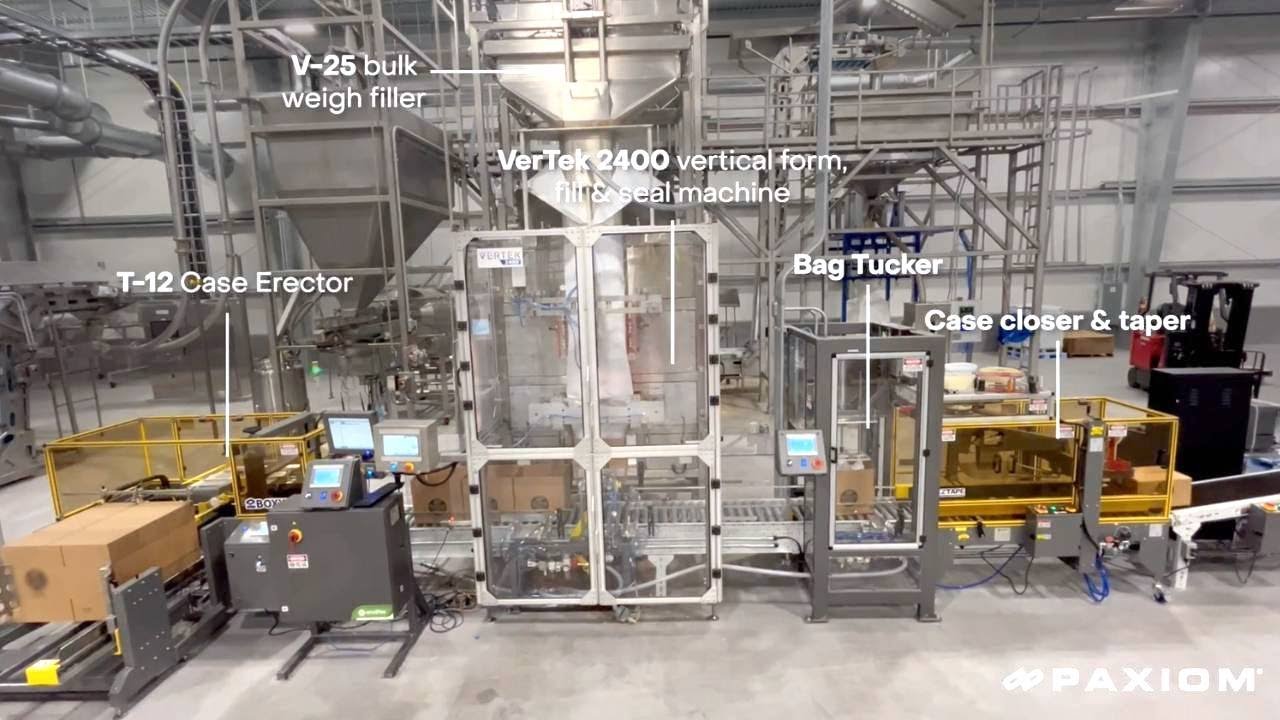

V-25/T-25 BULK WEIGH FILLER

BULK AND FOOD SERVICE PACKAGING

Automatically fill cases and totes with the V and T series bulk filling machine. The robust V (vibratory) and T (tote filling) 25 model automatic weigh filling machines are engineered for large format filling applications.

From 5 lbs to 50 lbs, the PrimoLinear is perfect for wholesale, institutional and food service requirements. Common packaging applications include weigh filling chocolates, candy, frozen foods, vegetables, fruits, baked goods, snack foods, ingredients, chemicals and much more.

Videos

Features

- 25L weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

Our V-25 is suited for all industries as your go to solid weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 25L weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

- Ideal Markets

Our V-25 is suited for all industries as your go to solid weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

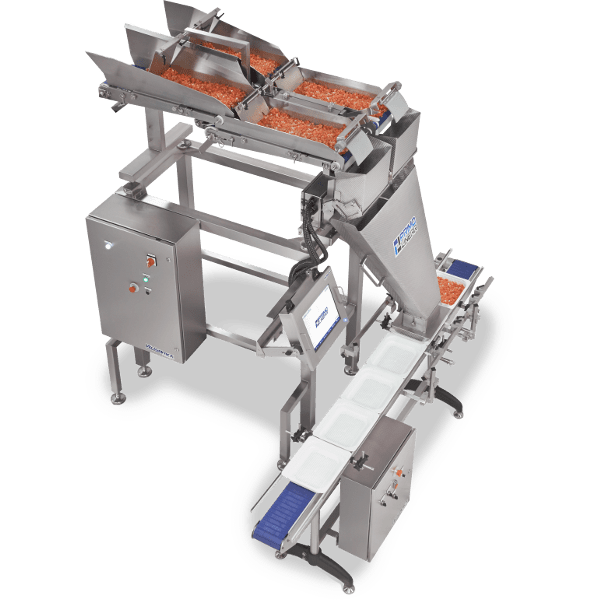

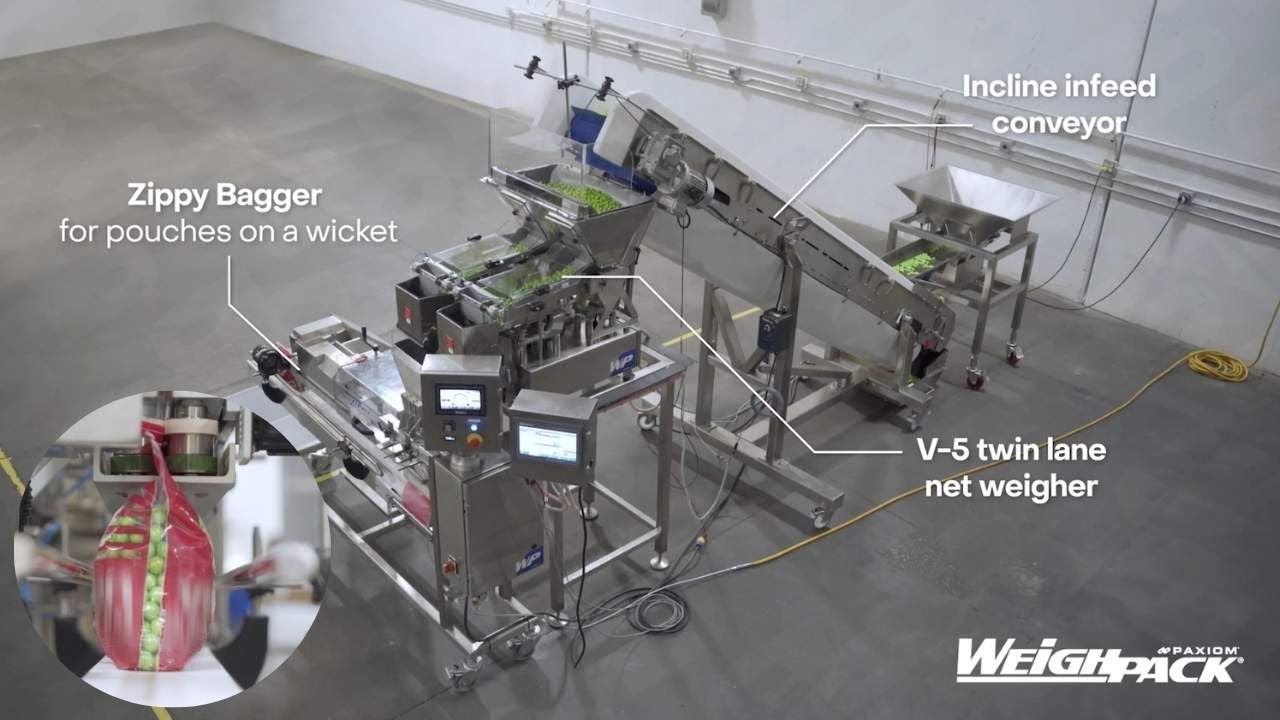

CONVEYORIZED WEIGH FILLER

FOR DIFFICULT TO MOVE PRODUCTS

Specifically engineered for weigh filling sticky, damp, wet and difficult to move products as well as delicate product requiring the gentle handling.

The PrimoLinear C and IW Series weigh filling machines use conveyor belts as opposed to traditional vibratory feed pans to carry product to the weighing station.

Commonly used fresh cut fruits and vegetables, shredded cheese, fresh meat, poultry and seafood, standard features include stainless steel frame, easily removable conveyor belts, large color touch screen, PC controls, production reporting and online support.

Videos

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

V-MINI WEIGH FILLER

FOR MINOR INGREDIENT FILLING

Weigh filler is ideal for accurately dispensing ingredients and small weighments.

Very accurate, it can dispense weights as small as one gram and reads in 1/100th of gram increments.

Typical applications include nuts, dried fruits, seasonings, confections, chocolate, spices, herbs diced meats, cheese and pharmaceuticals.

Features

- Digital independent vibrator speed control

- Adjustable electronic filtering

- Multi-speed control

- 304 stainless steel contact parts

- 304 stainless frame

- V-shaped dribble pan

- Compact design

- Too-less removable buckets

- Too-less removable funnel

- PC controls with Windows platform

*Rates subject to package style, type and size

Our V-Mini is suited for all industries as your go to ingredient filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Digital independent vibrator speed control

- Adjustable electronic filtering

- Multi-speed control

- 304 stainless steel contact parts

- 304 stainless frame

- V-shaped dribble pan

- Compact design

- Too-less removable buckets

- Too-less removable funnel

- PC controls with Windows platform

*Rates subject to package style, type and size

- Ideal Markets

Our V-Mini is suited for all industries as your go to ingredient filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

V-5 WEIGH FILLER

COMPACT AND EASY TO USE

Videos

Automatic weigh filling machine is designed to accurately dispense and fill a wide range of products into bags, cartons, trays, boxes, jars and containers.

The PrimoLinear will accurately weigh, dispense and package nuts, snack foods, candy, hardware, frozen foods, vegetables, fruits, meat, poultry, ingredients, spices, coffee, powders, granules, pet food and much more.

Designed for long term use and dependability the PrimoLinear includes a stainless steel frame, tool-less tilting hopper that requires no change-over when running multiple applications; tool-less removable contact parts, and standardized components that reduce maintenance costs.

Features

- 5 quart (5L) weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

Our V5 Net Weigher is suited for all industries as your go to net weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 5 quart (5L) weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

- Ideal Markets

Our V5 Net Weigher is suited for all industries as your go to net weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

V-25 BULK WEIGH FILLER

BULK AND FOOD SERVICE PACKAGING

Videos

Automatically fill cases and totes with the V and T series bulk filling machine. The robust V (vibratory) and T (tote filling) 25 model automatic weigh filling machines are engineered for large format filling applications.

From 5 lbs to 50 lbs, the PrimoLinear is perfect for wholesale, institutional and food service requirements. Common packaging applications include weigh filling chocolates, candy, frozen foods, vegetables, fruits, baked goods, snack foods, ingredients, chemicals and much more.

Features

- 5 quart (5L) weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

Our V-25 is suited for all industries as your go to solid weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 5 quart (5L) weigh bucket volume

- 304 Stainless steel frame

- 304 Stainless steel contact parts

- Quick access drawer for vibrator controls and load cell card

- Single pan configuration

- Color touch screen

- All-in-one tilt-able hopper

- Tool-less weigh bucket, and funnel removal

- Microprocessor controls

*Rates subject to package style, type and size

- Ideal Markets

Our V-25 is suited for all industries as your go to solid weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

CONVEYORIZED WEIGH FILLER

FOR DIFFICULT TO MOVE PRODUCTS

Videos

Specifically engineered for weigh filling sticky, damp, wet and difficult to move products as well as delicate product requiring the gentle handling.

The PrimoLinear C and IW Series weigh filling machines use conveyor belts as opposed to traditional vibratory feed pans to carry product to the weighing station.

Commonly used fresh cut fruits and vegetables, shredded cheese, fresh meat, poultry and seafood, standard features include stainless steel frame, easily removable conveyor belts, large color touch screen, PC controls, production reporting and online support.

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.