BINGO BAGGER

Vacuum Sealed Bagging

Designed for applications that do not require sealing to integrate with an existing sealer or locking device, the Bingo Bagger premade wicket pouch bagging machine automatically pulls a vacuum and/or gas flush at the sealing station. This convenient feature is unique in today’s market and greatly reduces labor while improving food safety by eliminating human interaction in the sealing process.

Manufactured with a robust stainless steel frame and food-grade contact parts, the Bingo can fill both polyethylene and laminate materials.

The Bingo Bagger is perfect for foodservice packaging, bulk bagging and is commonly used for cheese, fresh fruits and vegetables as well as meat and poultry.

Videos

Features

- Robust 304 stainless steel frame

- Compact foot print

- Remove-able product funnel

- Quick change over design

- Bag holding device with micrometer wheel for exact adjustment

- Stepper motor assembly and waste basket

- Omron PLC

- Color touch screen

- Rotary cylinders for finger rotation

- Bag support roller conveyor

- Menu driven controls with memory storage

- Stationary bag seal station

- Independent pneumatic knife assembly

- Digital temperature control

- Available: Upgrade to Vacuum/gas flush snorkel assembly

*Rates subject to package style, type and size

Our Bingo Bagger is suited for all industries as your go to vacuum wicket bag filling and sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Robust 304 stainless steel frame

- Compact foot print

- Remove-able product funnel

- Quick change over design

- Bag holding device with micrometer wheel for exact adjustment

- Stepper motor assembly and waste basket

- Omron PLC

- Color touch screen

- Rotary cylinders for finger rotation

- Bag support roller conveyor

- Menu driven controls with memory storage

- Stationary bag seal station

- Independent pneumatic knife assembly

- Digital temperature control

- Available: Upgrade to Vacuum/gas flush snorkel assembly

*Rates subject to package style, type and size

- Ideal Markets

Our Bingo Bagger is suited for all industries as your go to vacuum wicket bag filling and sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

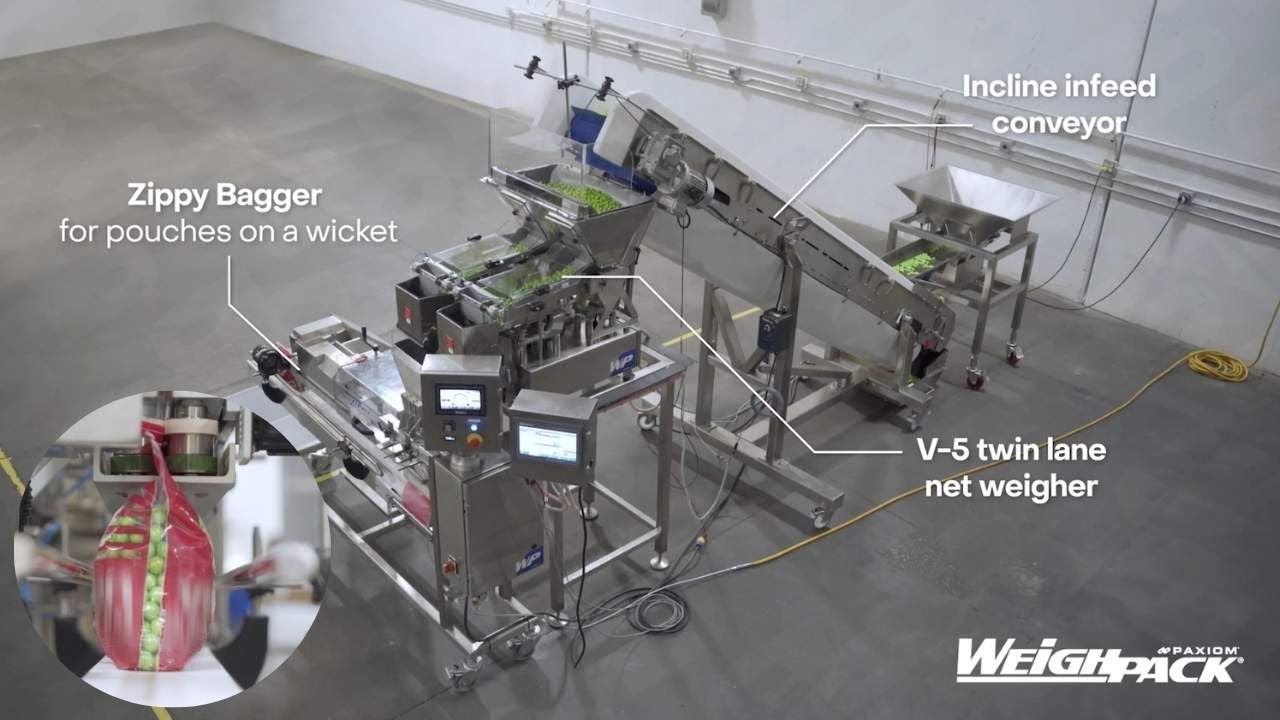

Zippy Bagger

Intermittent Sealing Jaws

The low-profile, compact Zippy Bagger wicket bag filling machine is designed to fill premade wicket pouches with or without zippers at rates of up to 2,000 bags per hour.

The Zippy automatically opens, fills and seals both laminated and polyethylene materials and is commonly used for filling products such as frozen foods, hardware, injection-molded pieces, baked goods and snack foods.

Videos

Features

- Omron PLC

- Fully adjustable wicket assembly

- Right to left bag transfer

- No bag—no fill control

- Air amplifier, regulator, lubricator, and filter

- Fully adjustable bag-clamping device

- Horizontal linear shaft support mechanism

- Stainless steel / anodized aluminum construction with water-tight control box

- Four pivoting casters with locks

- Hinged top with locking mechanism & Plexiglas window around fill zone

- 1 /4 “ seal width

- Rotary trim knife

- Adjustable angle grip fingers

- Integrated bag carrying conveyor

- Digital temperature control

*Rates subject to package style, type and size

Our Zippy Bagger is suited for all industries as your go-to wicket bag filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- Fully adjustable wicket assembly

- Right to left bag transfer

- No bag—no fill control

- Air amplifier, regulator, lubricator, and filter

- Fully adjustable bag-clamping device

- Horizontal linear shaft support mechanism

- Stainless steel / anodized aluminum construction with water-tight control box

- Four pivoting casters with locks

- Hinged top with locking mechanism & Plexiglas window around fill zone

- 1 /4 “ seal width

- Rotary trim knife

- Adjustable angle grip fingers

- Integrated bag carrying conveyor

- Digital temperature control

*Rates subject to package style, type and size

- Ideal Markets

Our Zippy Bagger is suited for all industries as your go-to wicket bag filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

VS BAGGER

Continuous High Speed Bagging

The VS Bagger (very simple) is the perfect partner to an existing sealing machine or for applications that do not require sealing at all. The VS automatically positions and fills a premade wicket pouch under the fill zone then transfers it to the next station of the packaging process. Reliable and compact, this versatile bagging machine can be easily interfaced with a twist tie, tin tie, Kwik-Lok or horizontal sealer.

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

Our VS bagger is suited for all industries as your go to continuous high speed bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

- Ideal Markets

Our VS bagger is suited for all industries as your go to continuous high speed bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

BINGO BAGGER

Vacuum Sealed Bagging

Videos

Designed for applications that do not require sealing to integrate with an existing sealer or locking device, the Bingo Bagger premade wicket pouch bagging machine automatically pulls a vacuum and/or gas flush at the sealing station. This convenient feature is unique in today’s market and greatly reduces labor while improving food safety by eliminating human interaction in the sealing process.

Manufactured with a robust stainless steel frame and food-grade contact parts, the Bingo can fill both polyethylene and laminate materials.

The Bingo Bagger is perfect for foodservice packaging, bulk bagging and is commonly used for cheese, fresh fruits and vegetables as well as meat and poultry.

Features

- Robust 304 stainless steel frame

- Compact foot print

- Remove-able product funnel

- Quick change over design

- Bag holding device with micrometer wheel for exact adjustment

- Stepper motor assembly and waste basket

- Omron PLC

- Color touch screen

- Rotary cylinders for finger rotation

- Bag support roller conveyor

- Menu driven controls with memory storage

- Stationary bag seal station

- Independent pneumatic knife assembly

- Digital temperature control

- Available: Upgrade to Vacuum/gas flush snorkel assembly

*Rates subject to package style, type and size

Our Bingo Bagger is suited for all industries as your go to vacuum wicket bag filling and sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Robust 304 stainless steel frame

- Compact foot print

- Remove-able product funnel

- Quick change over design

- Bag holding device with micrometer wheel for exact adjustment

- Stepper motor assembly and waste basket

- Omron PLC

- Color touch screen

- Rotary cylinders for finger rotation

- Bag support roller conveyor

- Menu driven controls with memory storage

- Stationary bag seal station

- Independent pneumatic knife assembly

- Digital temperature control

- Available: Upgrade to Vacuum/gas flush snorkel assembly

*Rates subject to package style, type and size

- Ideal Markets

Our Bingo Bagger is suited for all industries as your go to vacuum wicket bag filling and sealing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

ZIPPY BAGGER

Intermittent Sealing Jaws

The low-profile, compact Zippy Bagger wicket bag filling machine is designed to fill premade wicket pouches with or without zippers at rates of up to 2,000 bags per hour.

The Zippy automatically opens, fills and seals both laminated and polyethylene materials and is commonly used for filling products such as frozen foods, hardware, injection-molded pieces, baked goods and snack foods.

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

Our Zippy Bagger is suited for all industries as your go-to wicket bag filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

- Ideal Markets

Our Zippy Bagger is suited for all industries as your go-to wicket bag filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

VS BAGGER

Continuous High Speed Bagging

Designed for ease of use, the VerTek 800 and 1200 series can produce pouches up to 12 inches wide in a variety of shapes and sizes including small format, pillow and gusseted pouches.

Engineered with a single piece 304 stainless steel frame; the VerTek is the industry’s easiest bagging machine to clean and offers convenient access for maintenance.

VerTek 800 for pouches up to 8 inches wide (200mm)

VerTek 1200 for pouches up to 12 inches wide (300mm)

Additional features include a 10-inch color touchscreen; quick disconnect sealing jaws and heating elements, a side access panel for easier maintenance and an integrated encoder.

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

Our VS bagger is suited for all industries as your go to continuous high speed bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

- Ideal Markets

Our VS bagger is suited for all industries as your go to continuous high speed bagging machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.