Ever since our establishment in 1991 WeighPack Systems Inc. has come a long way with our emphasis on providing a quality built horizontal form fill seal machine with innovative technology at reasonable prices. The technologies we offer are;

Weigh filling | Bagging | Conveying | Wrapping | Engineering and Integration

HORIZONTAL FORM FILL SEAL MACHINE PROCESS

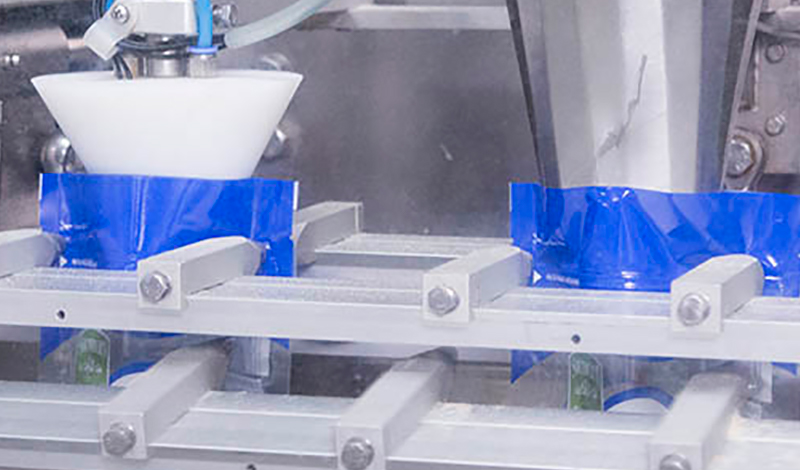

Each category has one to four packaging processes. Under the bagging class, one of these processes is what we refer to as Horizontal Form Fill Seal. Our horizontal form fill seal machine packaging system is our very own brand the R2B HFS Bagger. The high-performance, high-output R2B Horizontal Form Fill Seal Bagger makes, fills and seals pouches in a single process. Our R2B bagging machine is built to produce standup pouches (SUP, SURP), folder over pouches, pillow-shaped pouches, 3 sided seal pouches, and 4 sided seal pouches with zipper closures.

It is designed with a servo-driven technology that provides control and repeatable performance and speeds up to 120cpm. The main component when producing a wide range of pouch styles is a laminated roll stock film. Because of this, R2B eliminates the need for pre-made bags and reduces a considerable amount of material and labor cost.

R2B bagging machine

As a matter of fact, we could go as far as say that our R2B bagging machine is capable of saving our customers up to 30%. Since it produces a finished product equal to other bagging machines that require pre-made pouches. It also has standard features like Schnieider Servo Drives, large colored PLC touch screen, encoder positioning logic, heavy-duty stainless steel frame, components from Omron, SMC and Festo brand, and an adjustable bag width and length.

Our R2B bagger is available in 2 models. First is the R2B 1200 that creates bag widths of 6 to 12 inches and bag lengths of 8 to 18 inches. Similarly, the second, is the R2B 3600 that creates bag widths of 3.5 to 8 inches and bag lengths of 6 to 11 inches. Finally, other available options include stand-up pouch former, shaped bag molding device, hole punch, and gas flush. Also, middle capping device, vacuum station, tare notch and a zipper application device.