At WeighPack Systems, we manufacture a various selection of vertical bagging machines and cater to all industries and products including snack food, coffee, cheese, frozen foods, candy, chocolates, confections, seafood, powders, poultry, meat and more.

Our vertical bagging systems consist of two models:

VerTek | The XPdius

The VerTek series comes in four models, VerTek 800, 1200, 1600 and 2400. Each are built to produce a wide variety of pouch shapes and sizes including stick pack, pillow, and gusseted pouches.

Types of VerTek

VerTek 800 can produce pouches of up to 8 inches wide while VerTek 1200 can make pouches as wide as 12 inches. Both are constructed with a single piece 304 stainless steel frame which makes it easy to clean and durable. It also offer the benefit of high accessibility (convenient maintenance). The VerTek 800 and 1200 feature a 10” color touch screen, quick disconnect sealing jaws and heating elements, side access panel for easier maintenance, an integrated encoder, and more.

We also have the VerTek 1600 that can produce pouches up to 16 inches wide and is designed to pack large club size packages. It is usually used for filling large bags of salad, fresh vegetables, frozen foods, salt, meat, seafood and poultry. You can even add a carry handle to this heavy-duty welded machine for easier transport. Then last is our VerTek 2400 with its pouch production of 24 inches wide and is made with welded tubular steel construction. Thus making it perfect for bulk packaging applications. It is best for filling pouches with beer hop pellets, confections, pet food, rice, beans, flour, powders and polymers.

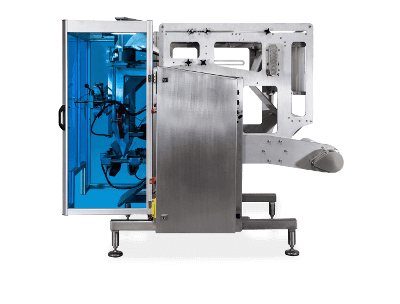

XPdius Elite 130

Finally, we have our user-friendly XPdius Elite 130 vertical bagging machine. Normally used for applications that require a production rate of 50 to 100 packages per minute, the XPdius Elite vertical form and seal machine can produce pouches up to 13 inches wide. Like the rest of our vertical bagging machines, XPdius is also constructed with a heavy-duty welded stainless steel frame. It is for durability, even under vigorous use. This machine has several important features. One is its tool-less removable vacuum pull belts for simple maintenance.

It also features servo-driven technology on the pull belts and sealing jaws that help optimize its speed and accuracy. Lastly, its open design gives way to a smooth film threading from back to front of the machine. Around the forming tube.