VERSAPAK

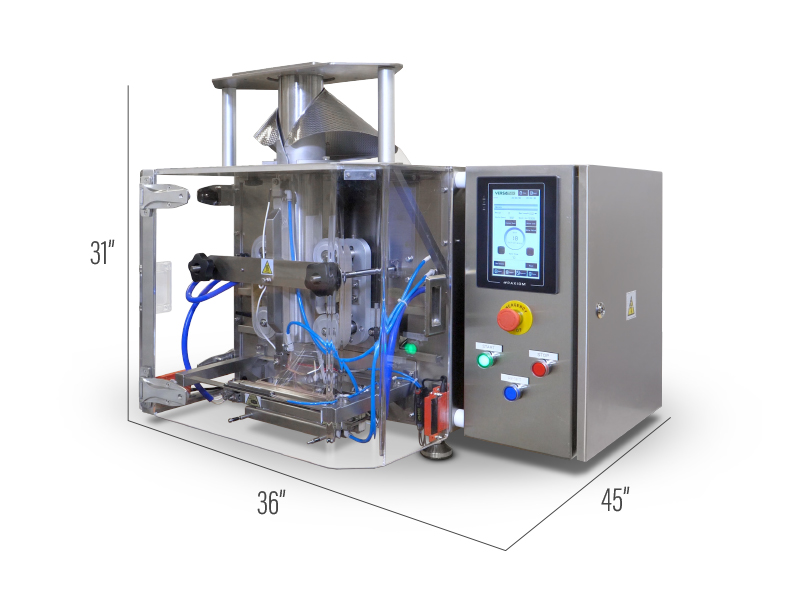

THE MOST COMPACT VERTICAL BAGGER

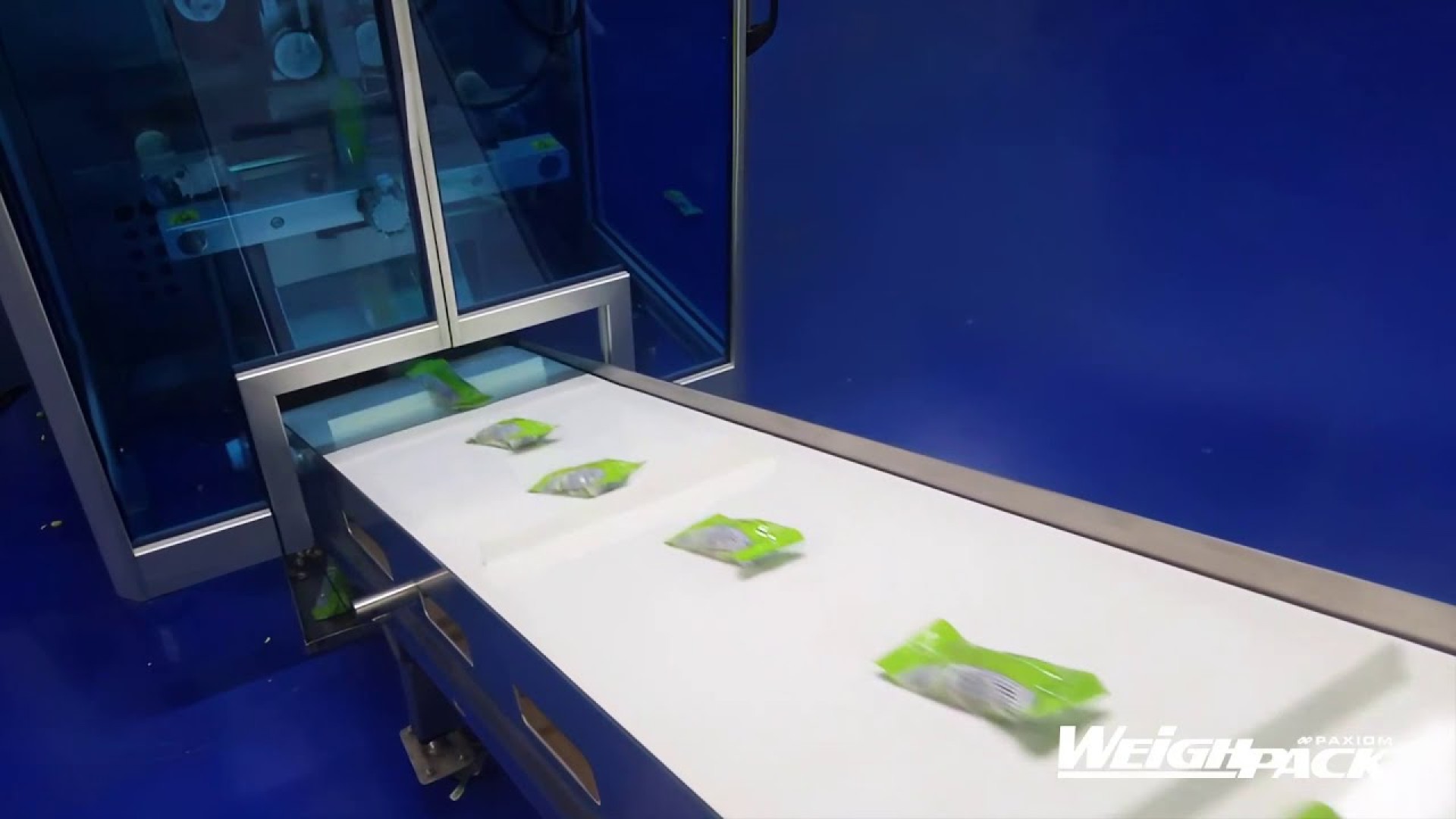

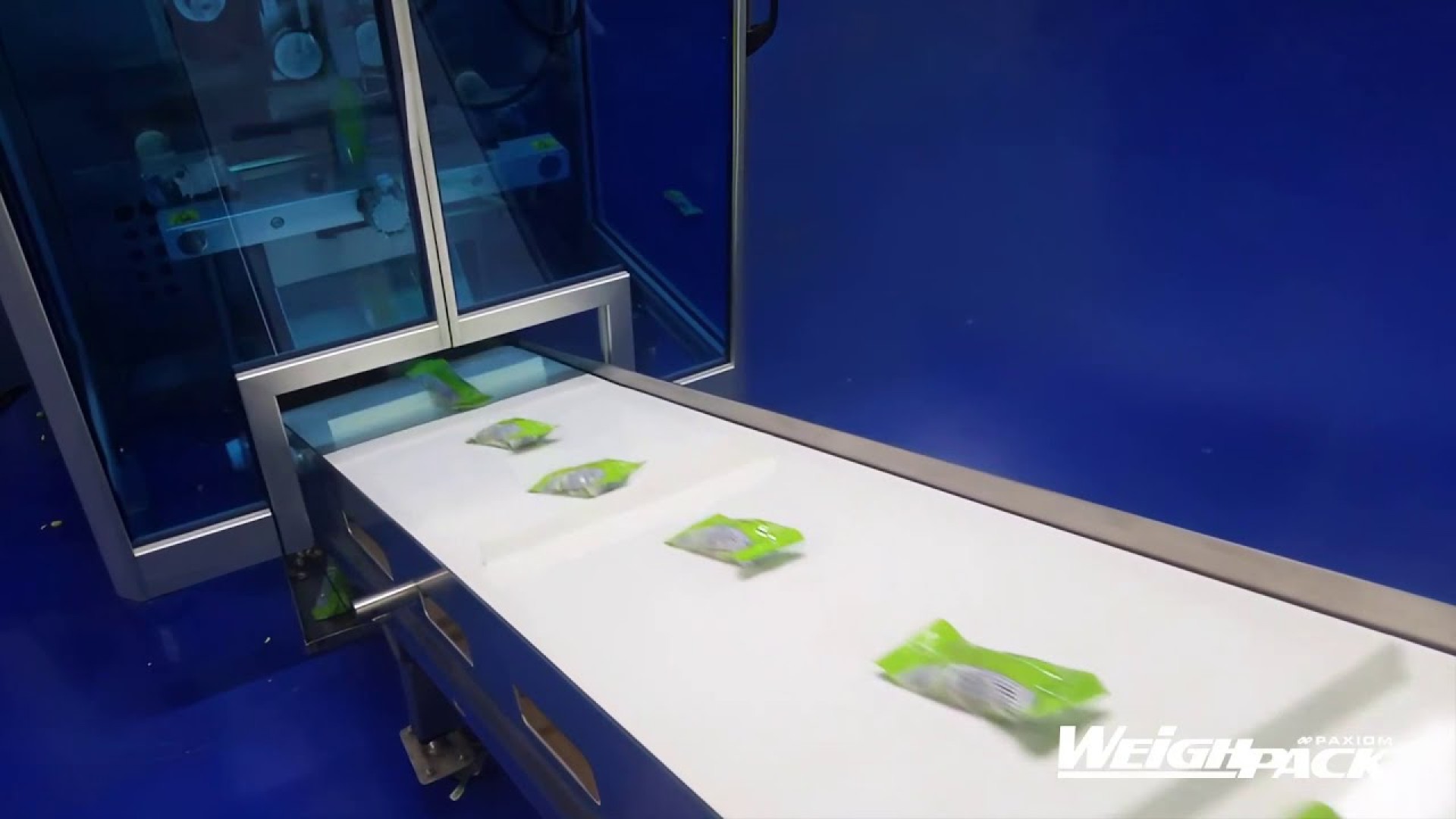

TThe VersaPak is the most compact vertical form, fill and seal machine designed to produce pillow bags. This simple and economical packaging machines is engineered for applications requiring flexibility, shorts runs, for hand or auto loading. Using non-proprietary flat roll stock film, pouch will be produced with top and bottom seals and a vertical back seal. This versatile bagger is easy to use, easy to clean and takes up very little space.

Also compatible with recyclable and compostable paper films, the VersaPak is a sustainable solution for modern packaging needs. It can also be easily integrated with a printer to apply real-time data like lot codes, expiry dates, and QR codes directly onto the pouch—perfect for traceability, branding, or consumer engagement.

Automatically package fruits, vegetables, snacks, candies, hardware, parts, tools, household goods, personal care items and anything else that needs automatic bagging.

For rates up to 20 pouches per minute

Videos

• 7” color touch screen

• Intelligent logic controller with HMI integrated temperature control

• Stainless steel frame sheet metal construction

• Liquid-cooled jaw provides pin stripe seal on laminate and poly film.

• SMC Pneumatics

• Bag length controlled by encoder (Eye mark – option)

• Air shaft film unwinding

• Clear Lexan front guard with safety switch

• Configurable recipes

• Adjustable back seal assembly

• Three run modes:

1. Full auto (Scale integration mode)

2. Foot pedal sealing sequence activation

3. Product presence detection sensor (option)

Our VersaPak is suited for all industries as your go to compact vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

• 7” color touch screen

• Intelligent logic controller with HMI integrated temperature control

• Stainless steel frame sheet metal construction

• Liquid-cooled jaw provides pin stripe seal on laminate and poly film.

• SMC Pneumatics

• Bag length controlled by encoder (Eye mark – option)

• Air shaft film unwinding

• Clear Lexan front guard with safety switch

• Configurable recipes

• Adjustable back seal assembly

• Three run modes:

1. Full auto (Scale integration mode)

2. Foot pedal sealing sequence activation

3. Product presence detection sensor (option)- Ideal Markets

Our VersaPak is suited for all industries as your go to compact vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

VF 1200

High Speed Continuous Motion Bagger

Engineered for high-speed applications, this continuous motion vertical form, fill and seal machine can handle multiple package formats and produces a wide range of package sizes providing flexibility for both retail and club size packaging, up to 150 bags per minute! The vertical sealing bars are continuously in motion so the film does not need to stop to receive its vertical seal.

For mechanical rates up to 9,000 bags per hour

Videos

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Heavy duty 304 stainless steel frame

- Right to left bag discharge

- Adjustable wicket pins

- No bag, no fill sensor

- Automatic bag opening

- Adjustable leveling feet with casters

- Carriage assembly

- Easy maneuverability

- Quick bag size change

- Omron PLC

*Rates subject to package style, type and size

- Ideal Markets

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

XPDIUS ELITE i-130

HIGH SPEED VERTICAL FORM & SEAL MACHINE

Designed to combine horizontal flow wrapping and vertical bagging in one compact machine, the Elite i130 is the most easily serviceable vertical bagging machine on the market today. This vertical form and seal machine is commonly used for high-speed applications ranging from 50 to 100 packages per minute and can produce pouches up to 13 inches (330mm) wide. Perfect for products such as frozen food, vegetables, snacks and pasta, it is as user-friendly as it is fast.

Machine features include a heavy-duty stainless steel frame with anodized aluminum side plates, precise control over seal jaw travel, toolless removable vacuum pull belts, air shafts that eliminate the need for side chucks, an open design for easy film threading and servo drives on both the pull belts and sealing jaws for increased speed and accuracy.

Available options include gas flushing, polyethylene seal assembly, hole punch, pivoting pouch support, bag squeezers to reduce air in the headspace, and provisions for code dating/printing devices.

Videos

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

Our XPDIUS ELITE 130 is suited for all industries as your go-to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

- Ideal Markets

Our XPDIUS ELITE 130 is suited for all industries as your go-to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

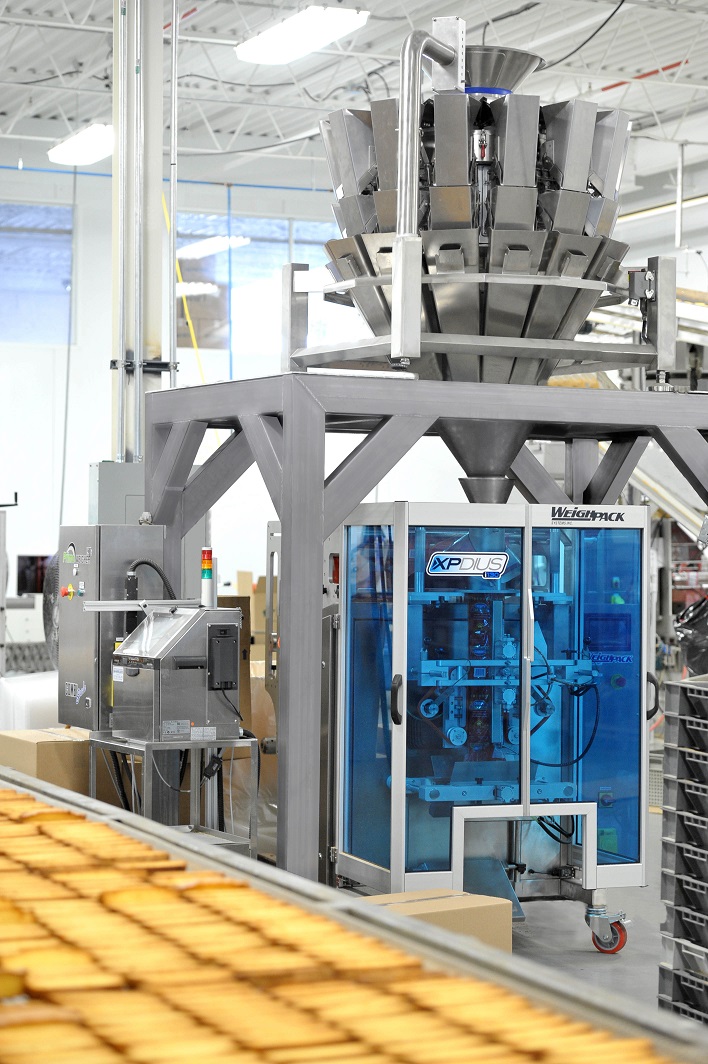

XPDIUS XPdius 1700

HIGH SPEED VERTICAL FORM & SEAL MACHINE

The XPdius vertical form and seal machine is designed for high speed applications and service-ability. Both sides of the machine open allowing easy access to all parts and assemblies inside the fame. The Xpdius 1700 is able to form and fill bags up to 17 inches wide.

Maintenance mechanics save hours of time with features like tool-less quick removal of change parts and design.

Videos

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Tool-less remove able forming collar

- Motor operated film unwind assembly for precise film tension control with triple rollers dancing bar

- Motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

*Rates subject to package style, type and size

Our XPdius 1700 is suited for all industries as your go to pocket depositing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Tool-less remove able forming collar

- Motor operated film unwind assembly for precise film tension control with triple rollers dancing bar

- Motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

*Rates subject to package style, type and size

- Ideal Markets

Our XPdius 1700 is suited for all industries as your go to pocket depositing machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

VERTEK 800 & 1200

VERTICAL FORM & SEAL MACHINE

Designed for ease of use, the VerTek 800 and 1200 series can produce pouches up to 12 inches wide in a variety of shapes and sizes including small format, pillow and gusseted pouches.

Engineered with a single piece 304 stainless steel frame; the VerTek is the industry’s easiest bagging machine to clean and offers convenient access for maintenance.

VerTek 800 for pouches up to 8 inches wide (200mm)

VerTek 1200 for pouches up to 12 inches wide (300mm)

Additional features include a 10-inch color touchscreen; quick disconnect sealing jaws and heating elements, a side access panel for easier maintenance and an integrated encoder.

Videos

Features

- Omron PLC

- 10.4” color touch screen

- Single piece 304 stainless steel frame

- SMC Pneumatics

- Thompson shafts and bushings

- HMI integrated temperature control

- Bag length control using encoder or eye mark

- Bag deflator—sponge

- Pneumatic film shaft

- Lexan safety guard with safety switch

- Memory based storage of operating functions

- Adjustable back seal assembly

- Auto-air regulator, filter, and lubricator

*Rates subject to package style, type and size

Our Vertek 800-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- 10.4” color touch screen

- Single piece 304 stainless steel frame

- SMC Pneumatics

- Thompson shafts and bushings

- HMI integrated temperature control

- Bag length control using encoder or eye mark

- Bag deflator—sponge

- Pneumatic film shaft

- Lexan safety guard with safety switch

- Memory based storage of operating functions

- Adjustable back seal assembly

- Auto-air regulator, filter, and lubricator

*Rates subject to package style, type and size

- Ideal Markets

Our Vertek 800-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

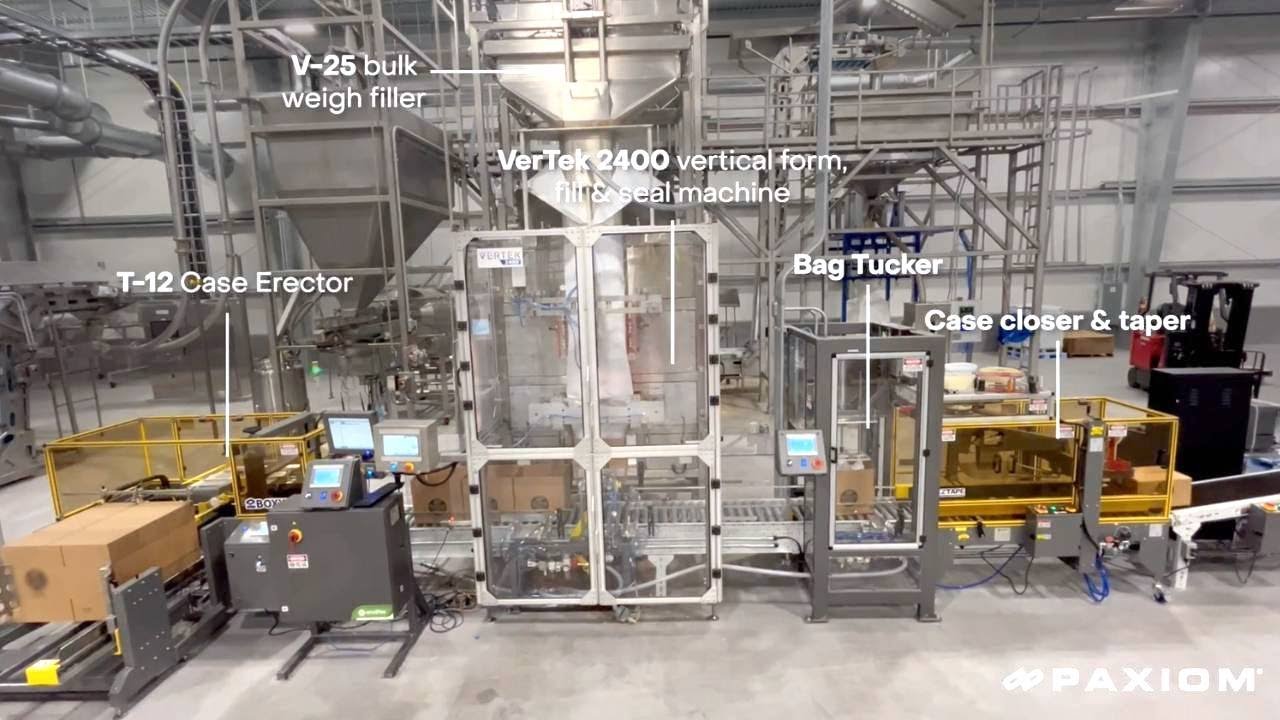

VERTEK 2400

VERTICAL FORM FILL & SEAL MACHINE

The heavy-duty VerTek 2400 vertical form, fill and seal machine is engineered for the toughest and heaviest of filling applications and can produce pillow or gusseted pouches up to 24 inches wide (600 mm). Its welded tubular steel construction makes it perfect for any bulk packaging application.

The robust 2400 has been used for beer hop pellets, confections, pet food, rice, beans, flour, powders and polymers and can seal a variety of film structures including laminate, metalized structures and polyethylene.

Videos

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

Our Vertek 2400 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Vertek 2400 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

We’re here to help

Want to see your product run on this machine?

VERSAPAK

THE MOST COMPACT VERTICAL BAGGER

Videos

The VersaPak is the most compact vertical form, fill and seal machine designed to produce pillow bags. Engineered to be manually or auto loaded, this bagging machine can sit on any surface and package your product effectively. Using non-proprietary flat roll stock film, pouches will be formed over the collar with back and horizontal seals. Producing up to 20 pouches per minute, this versatile bagging machine is easy to use, clean and change over.

Also compatible with recyclable and compostable paper films, the VersaPak is a sustainable solution for modern packaging needs. It can also be easily integrated with a printer to apply real-time data like lot codes, expiry dates, and QR codes directly onto the pouch—perfect for traceability, branding, or consumer engagement.

Automatically package fruits, vegetables, snacks, candies, hardware, parts, tools, household goods, personal care items and anything else that needs automatic bagging.

For rates up to 20 pouches per minute

FEATURES

• 7” color touch screen

• Intelligent logic controller with HMI integrated temperature control

• Stainless steel frame sheet metal construction

• Liquid-cooled jaw provides pin stripe seal on laminate and poly film.

• SMC Pneumatics

• Bag length controlled by encoder (Eye mark – option)

• Air shaft film unwinding

• Clear Lexan front guard with safety switch

• Configurable recipes

• Adjustable back seal assembly

• Three run modes:

1. Full auto (Scale integration mode)

2. Foot pedal sealing sequence activation

3. Product presence detection sensor (option)

Our VersaPak is suited for all industries as your go to compact vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

FEATURES

• 7” color touch screen

• Intelligent logic controller with HMI integrated temperature control

• Stainless steel frame sheet metal construction

• Liquid-cooled jaw provides pin stripe seal on laminate and poly film.

• SMC Pneumatics

• Bag length controlled by encoder (Eye mark – option)

• Air shaft film unwinding

• Clear Lexan front guard with safety switch

• Configurable recipes

• Adjustable back seal assembly

• Three run modes:

1. Full auto (Scale integration mode)

2. Foot pedal sealing sequence activation

3. Product presence detection sensor (option)- Ideal Markets

Our VersaPak is suited for all industries as your go to compact vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

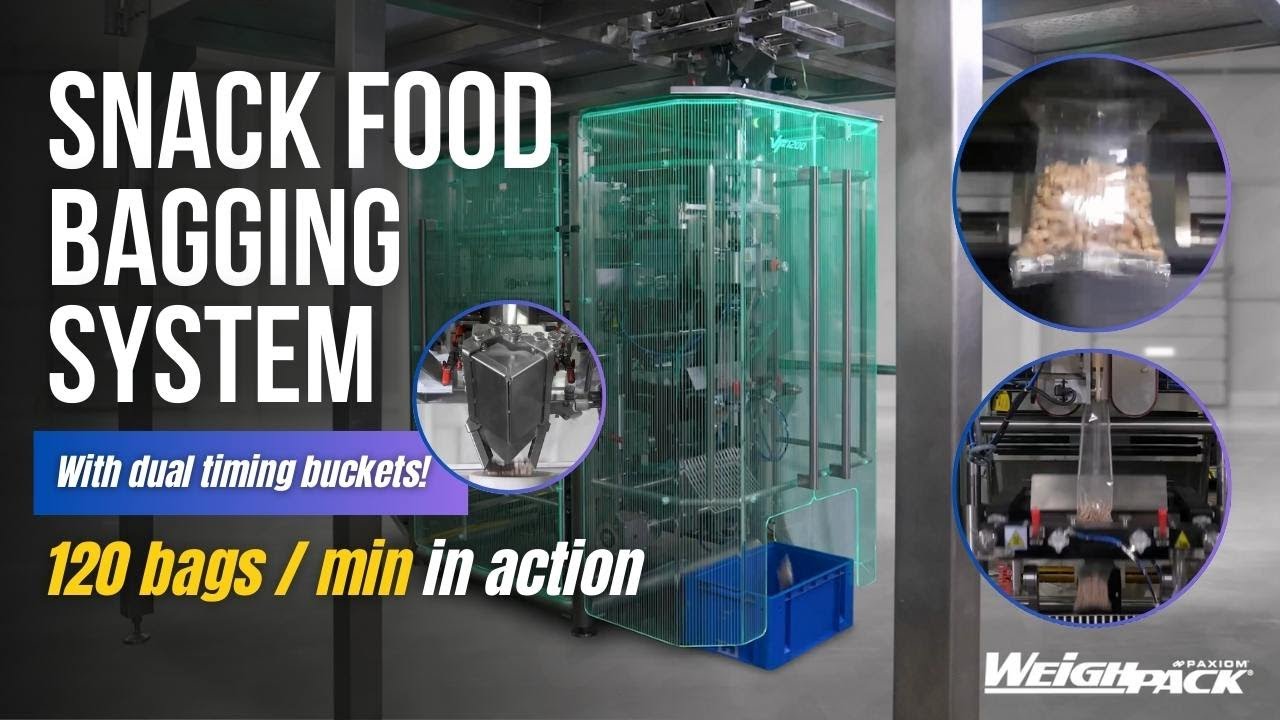

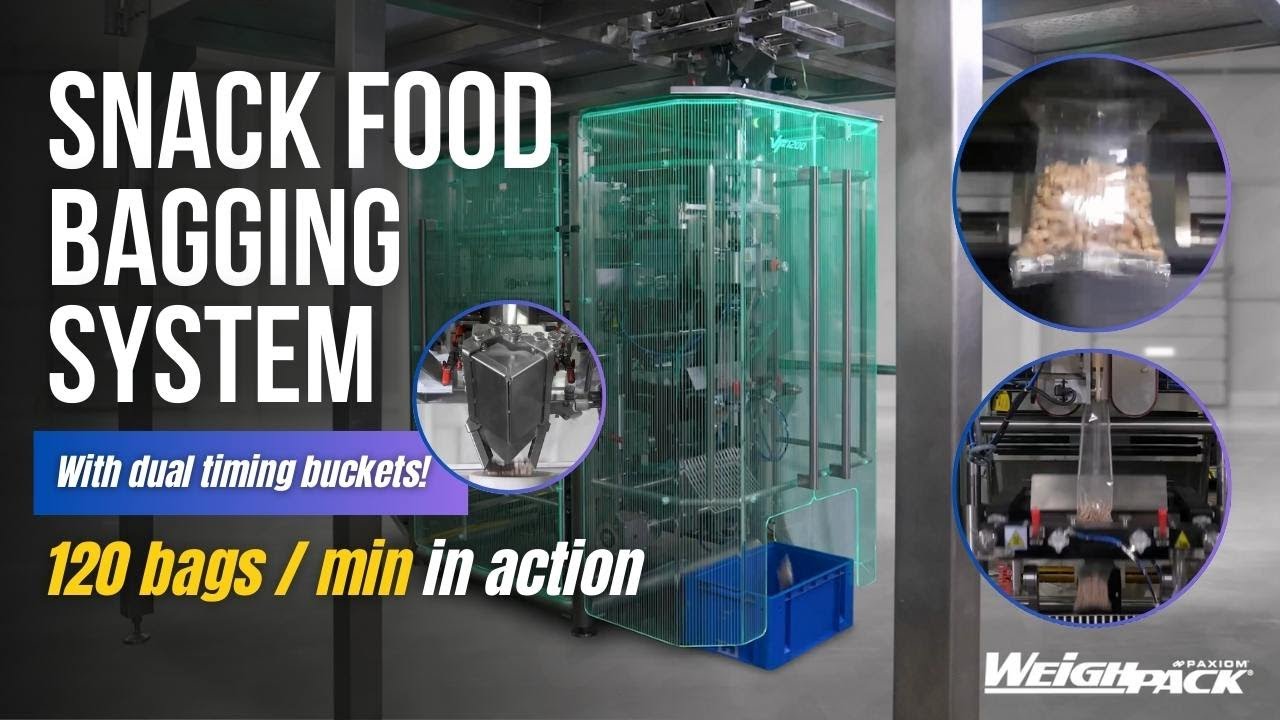

VF 1200

High Speed Continuous Motion Bagger

Videos

Engineered for high-speed applications, this continuous motion vertical form, fill and seal machine can handle multiple package formats and produces a wide range of package sizes providing flexibility for both retail and club size packaging, up to 150 bags per minute! The vertical sealing bars are continuously in motion so the film does not need to stop to receive its vertical seal.

For mechanical rates up to 9,000 bags per hour

Features

- Open frame design for easy access

- Omron PLC

- 15 inch touchscreen

- Omron motion controller and servos

- SMC pneumatic

- Becker vacuum system for pull belts

- 304 stainless steel frame

- Toolless removable vertical seal bar

- Toolless removable horizontal jaws

- Toolless removable forming shoulder

- High speed web alignment

- Film splicing station with vacuum cutting knife

- Film end detection

- Integrated film encoder

- Eye mark sensor for registered film

*Rates subject to package style, type and size

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Open frame design for easy access

- Omron PLC

- 15 inch touchscreen

- Omron motion controller and servos

- SMC pneumatic

- Becker vacuum system for pull belts

- 304 stainless steel frame

- Toolless removable vertical seal bar

- Toolless removable horizontal jaws

- Toolless removable forming shoulder

- High speed web alignment

- Film splicing station with vacuum cutting knife

- Film end detection

- Integrated film encoder

- Eye mark sensor for registered film

*Rates subject to package style, type and size

- Ideal Markets

Our VF-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

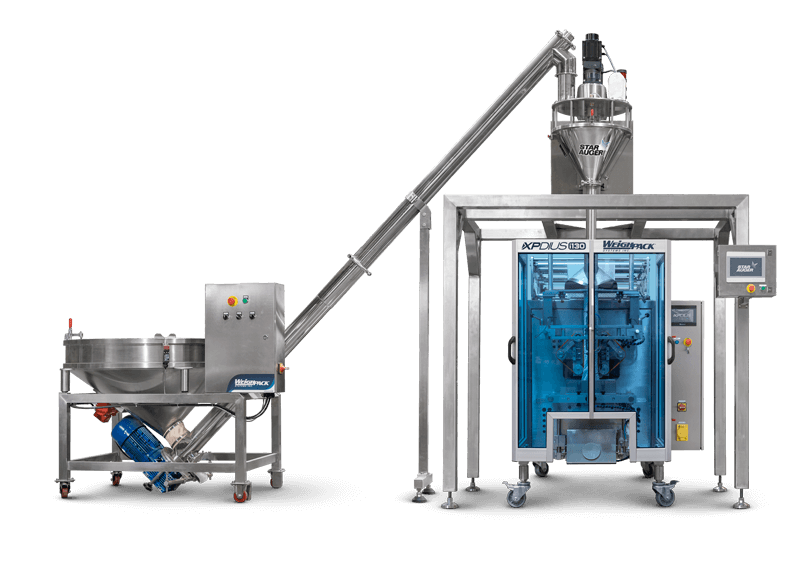

XPDIUS ELITE 130

HIGH SPEED VERTICAL FORM & SEAL MACHINE

Videos

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

Our XPDIUS ELITE 130 is suited for all industries as your go-to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Color touch screen and Omron PLC

- Two Panasonic servo motors to drive the film pull belts and operate the seal jaws

- Advanced automatic retractable pull belt assembly and vacuum pull belts

- Clamps for quick removal of forming shoulder and tube (tool-less)

- Motor operated film unwind assembly for precise film tension control

- Cantilever-mounted motorized film unwind roller

- Swing open control panel for dual side access to the inside mechanics

- Multi choice pre-programmed sequence of operation, seal above or below jaws

- 3 separate digital temperature controls integrated into touch screen

- Photo cell for bag registration

- Tool less removable pull belts

- Vacuum pull belts

- 304 Stainless steel frame

- Anodized aluminum film carriage (upgrade to 304 stainless steel available)

- Extruded aluminum lexan door assembly

*Rates subject to package style, type and size

- Ideal Markets

Our XPDIUS ELITE 130 is suited for all industries as your go-to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

VERTEK 800 & 1200

VERTICAL FORM & SEAL MACHINE

Videos

Designed for ease of use, the VerTek 800 and 1200 series can produce pouches up to 12 inches wide in a variety of shapes and sizes including small format, pillow and gusseted pouches.

Engineered with a single piece 304 stainless steel frame; the VerTek is the industry’s easiest bagging machine to clean and offers convenient access for maintenance.

VerTek 800 for pouches up to 8 inches wide (200mm)

VerTek 1200 for pouches up to 12 inches wide (300mm)

Additional features include a 10-inch color touchscreen; quick disconnect sealing jaws and heating elements, a side access panel for easier maintenance and an integrated encoder.

Features

- Omron PLC

- 10.4” color touch screen

- Single piece 304 stainless steel frame

- SMC Pneumatics

- Thompson shafts and bushings

- HMI integrated temperature control

- Bag length control using encoder or eye mark

- Bag deflator—sponge

- Pneumatic film shaft

- Lexan safety guard with safety switch

- Memory based storage of operating functions

- Adjustable back seal assembly

- Auto-air regulator, filter, and lubricator

*Rates subject to package style, type and size

Our Vertek 800-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- Omron PLC

- 10.4” color touch screen

- Single piece 304 stainless steel frame

- SMC Pneumatics

- Thompson shafts and bushings

- HMI integrated temperature control

- Bag length control using encoder or eye mark

- Bag deflator—sponge

- Pneumatic film shaft

- Lexan safety guard with safety switch

- Memory based storage of operating functions

- Adjustable back seal assembly

- Auto-air regulator, filter, and lubricator

*Rates subject to package style, type and size

- Ideal Markets

Our Vertek 800-1200 is suited for all industries as your go to vertical form fill and seal machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

VERTEK 2400

VERTICAL FORM FILL & SEAL MACHINE

Videos

The heavy-duty VerTek 2400 vertical form, fill and seal machine is engineered for the toughest and heaviest of filling applications and can produce pillow or gusseted pouches up to 24 inches wide (600 mm). Its welded tubular steel construction makes it perfect for any bulk packaging application.

The robust 2400 has been used for beer hop pellets, confections, pet food, rice, beans, flour, powders and polymers and can seal a variety of film structures including laminate, metalized structures and polyethylene.

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.

- Specifications

Features

- 10 quart (10L) weigh bucket volume

- Separate bulk & dribble settings

- Foot pedal activated or automatic dump cycle

- Reads in one gram increments

- Fully adjustable dwell time for weigh bucket door opening

- 304 stainless steel contact parts

- Off-center load-cell with overload protection

- Air regulator, filter, and lubricator

- Quick clamp weigh bucket

- Flow controls on pneumatic door opening assembly and bulk gate mechanism

- 304 Stainless steel frame

*Rates subject to package style, type and size

- Ideal Markets

Our Conveyorized Weigh Filler is suited for all industries as your go to conveying weigh filling machine:

- Bakery

- Beauty & Cosmetic

- Beverage & Liquid

- Bulk & Food Service

- Cannabis

- Cheese

- Coffee

- Confectionery

- Fruit & Vegetable

- Frozen Food

- Meaty & Poultry

- Pet Food

- Powder

- Snack Food

and many more industry applications.