In today’s tight labor market, manufacturers across all industries are facing a critical challenge: finding and retaining reliable workers for repetitive, manual tasks. Nowhere is this more evident than in packaging operations, where speed, accuracy, and consistency are non-negotiable—but staffing is increasingly unpredictable.

That’s where automation from companies like WeighPack Systems makes all the difference.

Labor Challenges Are Here to Stay

The current labor shortage isn’t just a passing phase. Factors like demographic shifts, rising wages, and increasing demand for flexible work are reshaping the workforce. Packaging departments are often the first to feel the pressure, with high turnover, absenteeism, and long hiring cycles.

Rather than continuing to fight for limited labor, forward-thinking manufacturers are leaning into automation to do more with less.

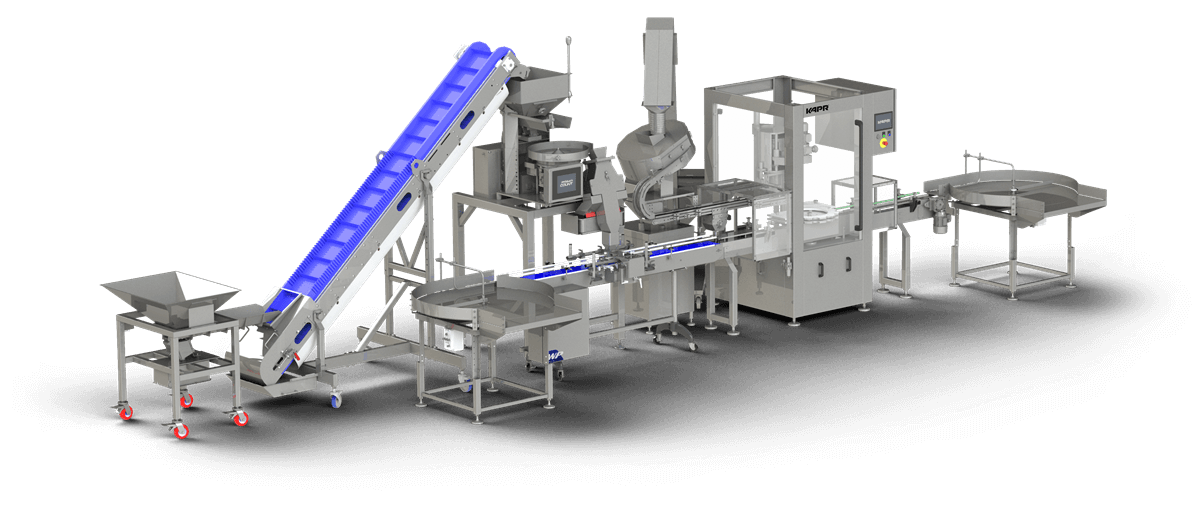

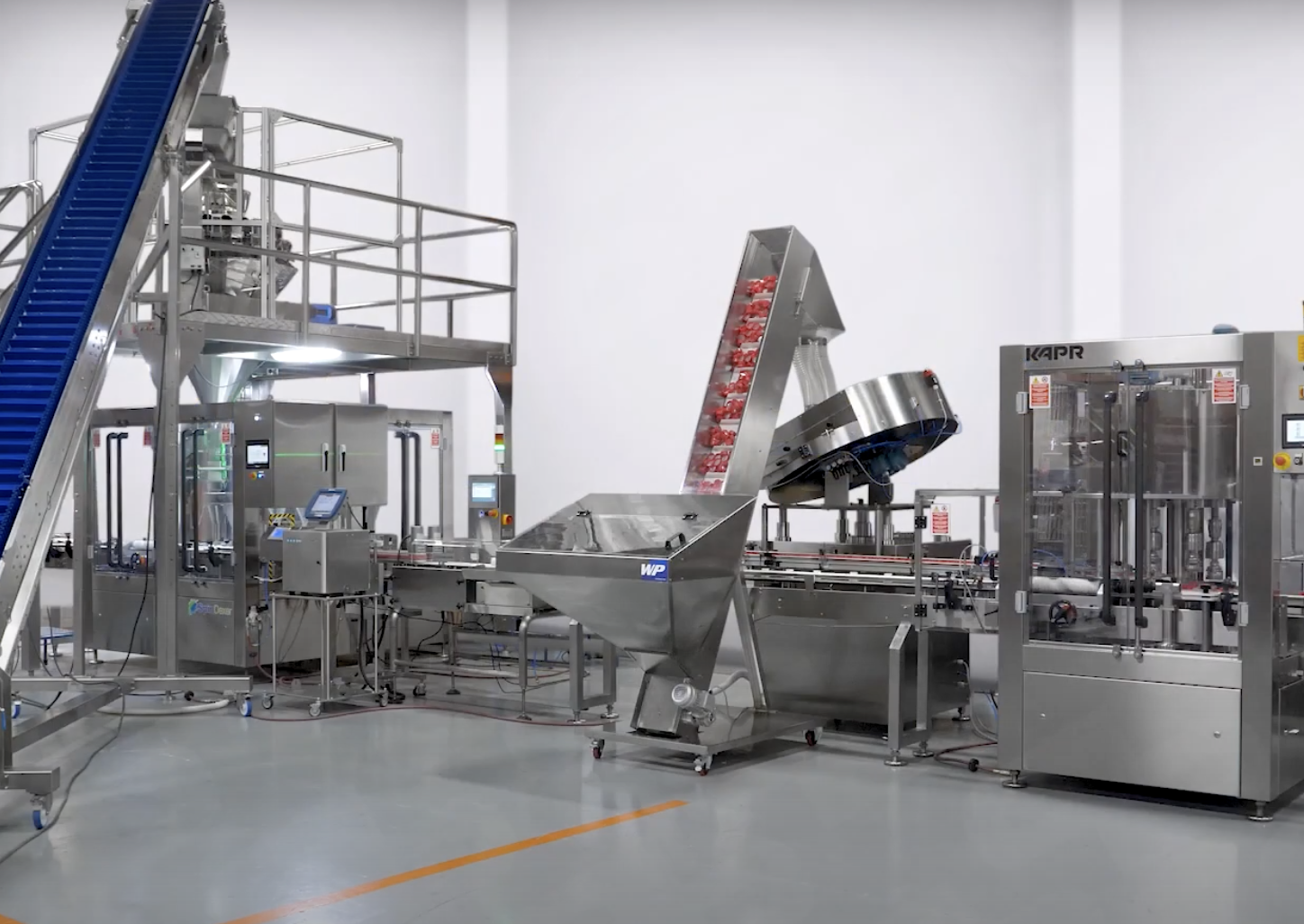

Full Primary Packaging Automation: One Line, Many Functions

WeighPack offers fully integrated solutions that automate every major function of primary packaging, from product dosing to finished pack-out:

- Product Feeding: Conveyors and feed systems deliver product consistently to the filling station.

- Weighing & Filling: Auger, vibratory, and multi-head weighers ensure accurate, repeatable portioning into jars, bags or pouches.

- Bagging & Wrapping: Vertical and horizontal form-fill-seal machines, Swifty premade pouch baggers and horizontal flow wrappers, eliminate manual filling and closing.

- Labeling & Printing: Integrated labelers and printers add product details, dates, and traceability data.

- Inspection & Rejection: Optional checkweighers, vision inspection, and metal detectors ensure quality and compliance.

The result is a streamlined line that can run with minimal operator intervention—freeing up staff to focus on value-added tasks instead of repetitive motion.

Not Just Faster—Smarter, Too

Automating your packaging isn’t just about speed. It’s about building resilience into your operations:

- 24/7 reliability regardless of shift availability

- Built-in consistency with fewer errors than human labor

- Faster changeovers between SKUs or product sizes

- Improved traceability and real-time monitoring

With WeighPack’s turnkey systems, manufacturers can ramp up production without ramping up headcount.

Real-World Impact

One WeighPack customer in the health supplement industry reduced their manual packaging crew by over 60% after installing a fully automated bagging and check weighing system. Another in frozen food industry eliminated hand scooping and sealing altogether, freeing their labor force for warehouse and shipping roles.

In each case, the goal wasn’t to replace people—it was to allocate people where they bring the most value.

Automation as a Recruitment Strategy

Paradoxically, investing in automation can also help attract better talent. Employees are more likely to apply for and stay in roles that offer:

- Modern technology and clean working environments

- Less physically demanding tasks

- Upskilling opportunities for line management and machine operation

Automation doesn’t eliminate jobs—it transforms them.

Winning the talent war isn’t about hiring more people. It’s about working smarter with the people you have. By automating primary packaging tasks, WeighPack helps manufacturers overcome labor volatility, reduce operating costs, and build lines that are faster, smarter, and more resilient.

Whether you’re packaging powders, snacks, pet food, cannabis, or anything in between, WeighPack has the technology to make labor a limiting factor of the past. Contact us today to discover how you can get started with automation—whether you’re looking for entry-level solutions or semi-automatic setups: https://www.weighpack.com/weighpack-sales-inquiries/.